Since December 2016, ARENA2036 has been the new research home and workplace for many scientists from the fields of industry and research who have come to our university campus in Stuttgart's suburb of Vaihingen. ARENA is an acronym standing for “Active Research Environment for Next-Generation Automobiles”. The mission of the research facility is to help make Industry 4.0 sustainable while promoting a technology revolution: individual mobility with low energy consumption. After all: the year 2036 will mark the 150th birthday of the automobile.

Germany's biggest “research factory” offers 10,000 m2 of space for theoretical reflection and practical application in four open-floor research areas: 1) Materials and Design, 2) Simulation and Digital Prototypes, 3) Production and the “Research Factory”, and 4) Creativity, Cooperation and Competency Transfer. Individual research projects have already taken shape in the massive hall, and their basic principles and feasibility are now undergoing testing.

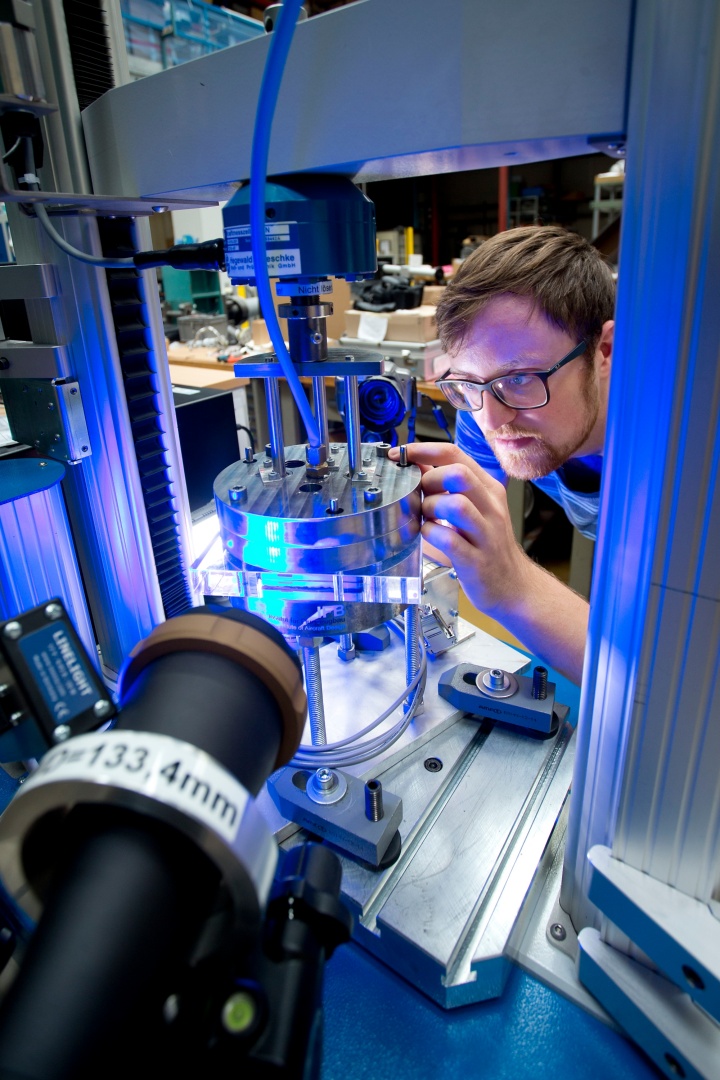

In future, driverless transportation will be a major feature of automobiles, which makes it a central object of study at the research stations of ARENA2036. Among the questions to be answered are: What is the best way to build such a system and subject it to loads, and what forces can it withstand? The sample automobile body shown here helps researchers find the answers.

Ideas unleashed: the work area shows that ARENA2036 has been designed as a cooperation platform to promote a new form of collaboration. Glass panes serve as office “walls”, and few barriers separate the offices, conference rooms, and work stations. Clearly there are no limits on ideas here, and the dearth of boundaries promotes a free give-and-take among the various research disciplines.

The first four start-up-projects at ARENA2036 are: LeiFu (Intelligent, Multi-Material Lightweight Design with Function Integration), ForschFab (Transformable Production in the "Research Factory", see photo), Khoch3 (Work Science Enhancement of a Creativity Work Environment), and DigitPro, where Prof. Peter Middendorf and his team from the Institute for Airplane Design are working on materials and processes for a digital prototype. Using this project as an example, the following pages show how work on tomorrow is already in progress today at ARENA2036.

DigitPro aims to increase efficiency and save resources by virtually predicting the entire value-added chain of an automobile structure. This new digital prototype forms a nucleus for virtual simulation models and CAM interfaces.

It permits elementary data transmission from one individual processing step and from each simulation program to another while documenting the finished simulation packages. The result is better-quality predictions, optimum component designs, and savings in costs and time.

Material modelling is followed by virtual processing steps which simulate the production of these materials and forms. Long before the corresponding lightweight design structures are actually used, such virtual material tests reveal properties and performance characteristics so that these can be evaluated and the follow-up processes optimized.

The virtual process chain culminates in a non-stop automatic transfer of all simulation data to production robots. This transfer is carried out through a new type of CAM interface which ensures that the actual component exactly replicates the one worked out virtually. The related data are no longer entered by hand but go directly to the production station at the push of a button, so to speak – a good start for Industry 4.0.

Currently it is planned to incorporate the results of the “Digital Prototype” project into a subsequent “Digital Fingerprint”project. The data structure already in place will be used and enhanced with new applications. The team is now working intensively to ensure a smooth transition between the two projects, and the first project phase will come to an end in 2018. ARENA2036 will then come under the sway of new project topics.