Carbon fiber composites are one of the main research topics at both the Institute of Aircraft Design at the University of Stuttgart and the Manufacturing Futures Research Institute at Swinburne University of Technology (SUT) in Melbourne. In 2017, the longtime cooperation between the institutes, based on personal contacts, turned into a formal collaboration, which includes ARENA2036 in addition to the two universities. Numerous companies are involved in this research campus at the University of Stuttgart. “The range of topics covered by our joint research has also expanded,” says Dr Boris Eisenbart, Associate Professor at SUT. For example, three current, closely interlinked research projects in cooperation with industrial partners from Australia, Germany, Israel, and Austria focus on digitalized production. The aim is to develop digital production processes to reduce the high cost of components made of carbon fiber composites. In the project “I4Production”, scientists are working on a “Cognitive Digital Twin” that is intended to mirror all parts of a production system virtually.

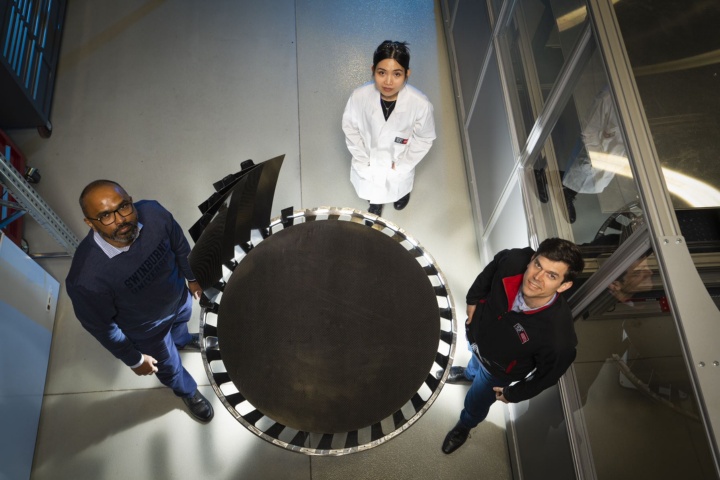

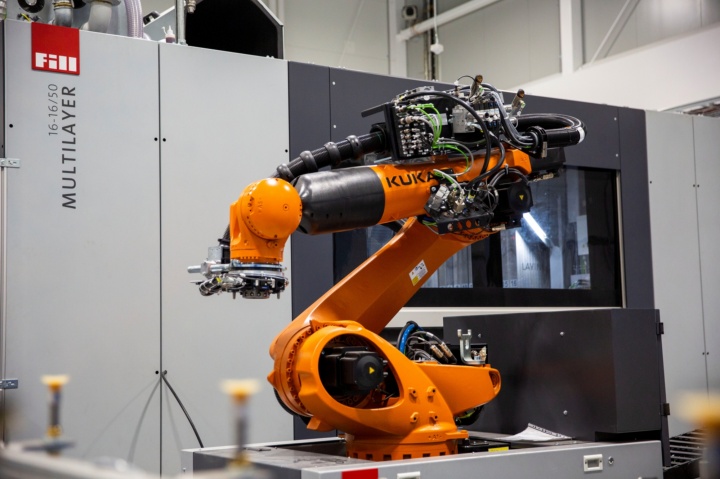

In the project “DIREKT”, form-adaptive tools are developed, among other things, to adapt to digital models automatically. Both research projects are based in Stuttgart and are funded by the Federal Ministry of Education and Research. The counterpart at SUT is a Global Innovation Linkages project funded by the Australian government. “We do research on the digital tracking of production processes: Which data from the huge data sets are meaningful, and what conclusions can be drawn from them?” Asks Eisenbart. In Swinburne’s new Industry 4.0 Testlab, which started operation in June 2021, carbon fiber composites are produced using an innovative 3D printing process. In two other collaborative projects, the two universities are developing components for laser drones as well as reinforcements for hydrogen pressure vessels.

In addition to the exchange of Bachelor’s and Master’s degree students, the cooperation also includes a double doctoral degree program, which currently has five participants. Prerequisite for admission is a Master’s degree. In Australia, however, Honors programs that lead directly from the Bachelor’s degree to the doctoral degree in four years are much more popular, says Eisenbart: “In this regard, we would like to see even more flexible solutions. Other than that, the cooperation is going great.”

Im Projekt DIREKT werden unter anderem formadaptive Werkzeuge entwickelt, die sich automatisch an digitale Modelle anpassen. Beide in Stuttgart angesiedelten Forschungsprojekte werden vom Bundesministerium für Bildung und Forschung gefördert. Gegenstück an der SUT ist ein von der australischen Regierung finanziertes Global-Innovation-Linkages-Projekt. „Wir forschen über die digitale Verfolgung von Produktionsprozessen: Welche Daten aus den riesigen Datenmengen sind aussagekräftig, welche Schlüsse lassen sich daraus ziehen?“, erläutert Eisenbart. Im neuen Industrie-4.0-Testlabor der SUT, das im Juni 2021 in Betrieb ging, werden Kohlefaser-Verbundwerkstoffe in einem innovativen 3D-Druckverfahren hergestellt. In zwei weiteren Kooperationsprojekten entwickeln die beiden Hochschulen Bauteile für Lastendrohnen und Hüllen zur Verstärkung von Wasserstoff-Druckbehältern.

Neben einem Austausch von Bachelor- und Masterstudierenden umfasst die Kooperation auch ein Doppelpromotionsprogramm mit fünf Teilnehmenden. Voraussetzung für die Zulassung ist ein Masterabschluss, in Australien seien jedoch „Honours“-Programme, die vom Bachelor-Abschluss in vier Jahren direkt zur Promotion führen, wesentlich beliebter, erläutert Eisenbart: „In diesem Punkt würden wir uns noch flexiblere Lösungen wünschen. Ansonsten läuft die Zusammenarbeit wunderbar.“

(c) Deutscher Akademischer Austauschdienst (DAAD), GATE-Germany Länderprofil Australien (german) , Miriam Hoffmeyer