Organisms that need CO2 to grow reduce the climate-damaging gas and thus global warming. Even microscopic organisms can contribute by sequestering CO2 as biomass. In order to ensure that these microorganisms have the optimal conditions to form sufficient biomass despite their minimal size, the German Research Foundation (DFG) is funding researchers from the University of Stuttgart, the Technical University of Hamburg (TUHH) and the Technical University of Munich (TUM) as well as other research institutions in the priority program “InterZell” for another three years to investigate scale-up and process optimization.

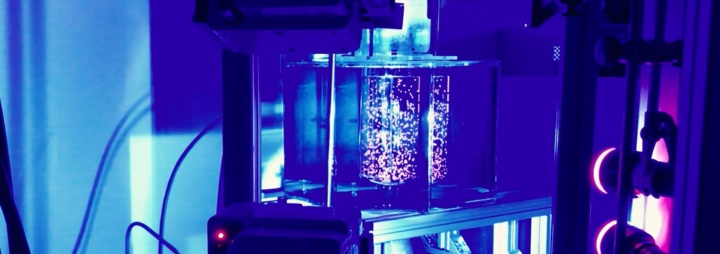

As a climate-damaging gas, CO2 contributes to the greenhouse effect. Because of the increased concentration of CO2 in the atmosphere, the ecological balance has shifted; climate warming and the melting of glaciers are the consequences. Plants use CO2 to produce carbohydrates and oxygen through photosynthesis; CO2 is thus bound in biomass. Some microorganisms also require CO2 for their growth in order to produce biomass from it. They are able to do so far more efficiently than plants growing on the ground. This is where the research of “InterZell” comes in: Following the example of nature, the researchers want to investigate how microorganisms support each other when it comes to growth and product formation. Bioreactors are used to study high cell number and biomass under targeted conditions.

Partner organisms supply each other

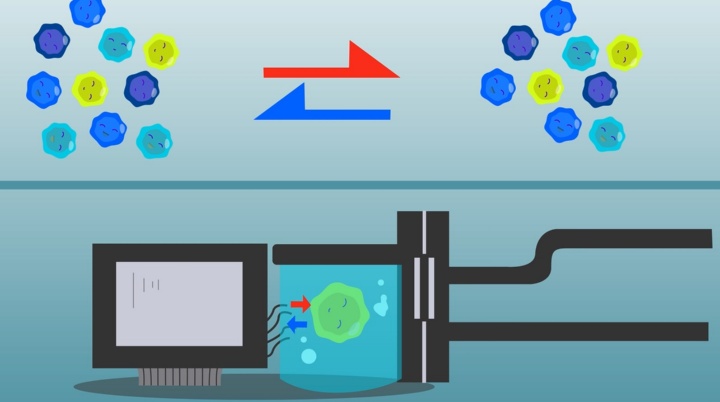

Conditions for growth and product formation in large bioreactors are often less than optimal because of limited oxygen or nutrients as a result of poor mixing inside the bioreactor. The project “Coconut” (cell–cell interactions in a synthetic co-culture PHA production by sunlight and CO2 in an artificial co-culture of Synechococcus elongatus and Pseudomonas putida) of the TUM within the “Interzell” priority program thus entails cultivating two partner organisms together in the bioreactor. The researchers want to simulate an ecological equilibrium in which an autotrophic microorganism (i.e., one that lives on sunlight and CO2) supplies its tandem partner with sugars and metabolites – a well-known principle from nature. The first tests have been successful. It was shown how cyanobacteria fix CO2 and supply other microorganisms with the help of sunlight by photosynthesis – just like terrestrial plants. During stress (e.g., salt stress), the bacterium increasingly forms sugars such as sucrose. This is transported out of the cell by the genetically modified bacteria and is thus made available to a partner organism, a heterotrophic soil bacterium (Pseudomonas putida), which is a known producer of bioplastics. The model combination of two microorganisms shows that autotrophic and heterotrophic microorganisms can be co-cultivated in the laboratory in a resource-saving manner. In the next three-year funding phase, the task now is to transfer this into practice.

Customized scale-up in the bioreactor

Process parameters such as oxygen supply or mixing are essential for the tiny organisms to be able to thrive in the bioreactor. However, perfectly adapting and controlling process control is often difficult in industrial practice. In order to conserve materials and the environment, research is first carried out on a small laboratory scale. The laboratory results are then transferred to a large bioreactor of several tens to hundreds of thousands of liters. In order for processes that work well on a small scale to succeed on a large scale, a customized scale-up from laboratory to industrial production is needed. This is where the research of the CHOLife project (Experimental Multi-scale Analysis and Simulation of Lifelines in the Bioreactor) comes in. Scientists from the TUHH and the University of Stuttgart are investigating scale-up using the example of the immunoglobulin IgG1. “There is a great need for research and cooperation in order to transfer the results that work on a miniature scale to an industrial scale,” says Prof. Ralf Takors, the coordinator of the 2170 priority program, and Dr. Martina Rehnert, the project manager responsible for networking among the researchers, both from the Institute of Biochemical Engineering at the University of Stuttgart.

Sustainability also in the second funding period

Coconut and CHOlife are two of 10 research projects with a total of 50 scientists funded by the DFG in the InterZell priority program (SPP 2170) for a second funding period of three years. In order increase the sustainable production of active ingredients in the bioreactor, model parameters in the bioreactor are investigated for transfer into practice.

Expert Contact:

Prof. Dr. Ralf Takors, Dr. Martina Rehnert, Coordination of the SPP Project “InterZell”, University of Stuttgart, Institute of Biochemical Engineering, phone: +49 711 685 69925, e-mail