Project Description

livMatS Biomimetic Shell

FIT Freiburg Center for Interactive Materials and Bioinspired Technologies,

University of Freiburg, 2023

The livMatS Biomimetic Shell at the FIT Freiburg Center for Interactive Materials and Bioinspired Technologies is a pioneering research building. The generous space, which flows smoothly into the surrounding campus, serves as an architectural incubator for the development of innovative, cross-disciplinary research ideas. Simultaneously, the building itself represents a research project of the two Clusters of Excellence, Integrative Computational Design and Construction for Architecture (IntCDC) at the University of Stuttgart and Living, Adaptive and Energy-autonomous Materials Systems (livMatS) at the University of Freiburg, which are investigating an integrative approach to design and construction for sustainable architecture. The building brings together the different research approaches of the two Excellence Clusters to achieve an architectural synthesis. Compared to a conventional timber building, the FIT Biomimetic Shell reduces the total environmental life cycle impact by 50%. The distinctive and highly resource-efficient segmented timber shell construction is fully deconstructible and reusable. It is made feasible through the integrative development of computational design methods, robotic prefabrication and automated construction processes, as well as novel forms of human-machine interaction in timber construction. Embedded in the wood shell is the “Solar Gate”, a large-scale skylight which contributes to the regulation of the indoor climate by means of a biomimetic, energy-autonomous, 4D-printed shading system. Together with an activated floor slab made of recycled concrete, this enables comfortable year-round use with minimal building services. The result is an expressive, flexible space and an architecture that shows alternative paths for sustainable construction, which will also serve as a platform for further research.

As the world's population continues to grow, the construction industry faces the challenge of using fewer resources and switching to sustainable materials. Scientists from the Universities of Stuttgart and Freiburg are developing new interdisciplinary approaches to construction for the future. In a joint project, the researchers have built a lightweight timber construction pavilion at the Faculty of Engineering at the University of Freiburg, where they are testing and researching new materials and construction methods. For the construction of the "livMatS Biomimetic Shell @ FIT", the scientists used new computer-based planning methods, robotic manufacturing and construction processes, and new forms of human-machine interaction, which enable significant resource savings compared to conventional timber construction. The pavilion, designed according to biomimetic principles, was created in a collaboration between the Clusters of Excellence Integrative Computational Design and Construction for Architecture (IntCDC) at the University of Stuttgart and Living, Adaptive and Energy-autonomous Materials Systems (livMatS) at the University of Freiburg.

Sustainable timber materials and optimised production

Over the past decade, timber construction has become increasingly important as a replacement for CO2-intensive building materials such as steel and concrete. The "livMatS Biomimetic Shell @ FIT" consists of hollow wooden cassettes, which minimize the use of materials for the building envelope and its weight. A detailed life cycle analysis shows that the building's material consumption is reduced by more than 50 percent and its global warming potential by almost 63 percent compared to a conventional timber building. "We have already used the material-efficient principle of the hollow cassette in a temporary, open structure for the 'BUGA Holzpavillon 2019', which we presented at the German National Garden Show 2019 in Heilbronn," says Prof. Achim Menges from the Institute for Computational Design and Construction (ICD) and spokesperson for the IntCDC Cluster of Excellence at the University of Stuttgart. "We have developed this principle for a permanent, closed building that can be used all year round. We have optimised this timber construction method by using more sustainable timber materials and by adapting the components to minimize waste during robotic production." The entire building structure is designed to be easily dismantled and reused, and its components remain sortable by material type.

Bioinspiration: The modular sea urchin skeleton

The modular structure and design are based on the construction principles of the sea urchin skeleton. It is made up of individually arranged plates, making it particularly light and strong. The careful use of scarce resources is a key evolutionary advantage of natural structures. "The pavilion shows how a load-adapted and material-efficient structure can be produced economically even under today's conditions. The key to this is the consistent digitalization of planning and production," says Prof. Jan Knippers of the Institute of Building Structures and Structural Design (ITKE) and deputy spokesperson of the IntCDC Cluster of Excellence at the University of Stuttgart.

Robotic fabrication and assembly

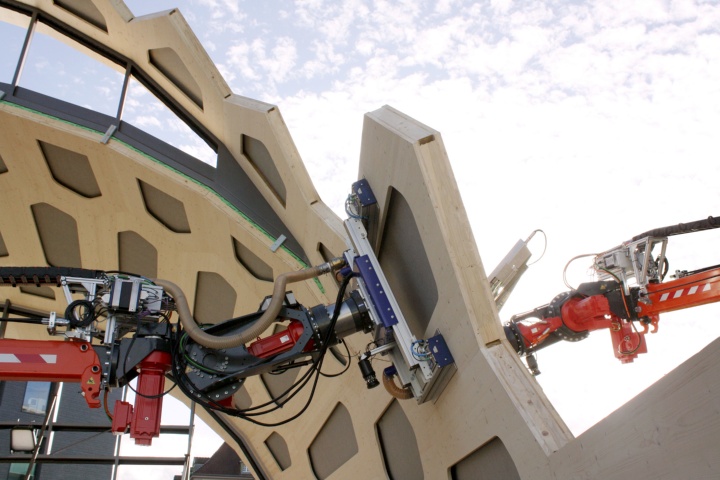

The components were manufactured on a newly developed, transportable robotic platform by cooperation partner müllerblaustein HolzBauWerke GmbH. Augmented reality was used to integrate manual partial assembly steps for special components such as lighting and acoustic elements. "This form of human-machine interaction in the manufacturing process enables the effective, digitally controlled production of complex components with a high degree of precision," says Menges. For the first time, automated hydraulic manipulators have been utilized in a real-life construction site setting for the "livMatS Biomimetic Shell @ FIT". The Institute for System Dynamics (ISYS) addressed the automation task and equipped the manipulators with special end effectors such as a vacuum gripper, which pick up components, automatically place them at the appropriate installation position and hold them in position until they are screwed into place by another manipulator. An important aspect is the localization and precision of the construction robots. "To ensure that these construction robots work precisely, we have developed an automated real-time total station network to determine their positions", says Prof. Volker Schwieger from the Institute of Engineering Geodesy (IIGS) at the University of Stuttgart.

A shading system that reacts to temperature and humidity protects the interior from the sun

"Our goal is to operate the pavilion in an energy-neutral way," says Prof. Jürgen Rühe from the Department of Microsystems Engineering and member of the spokesperson team of the livMatS Cluster of Excellence at the University of Freiburg. The building has a thermally activated floor slab made of recycled concrete, which heats and cools the building using geothermal energy. A weather-sensitive shading system made of bio-based, 4D-printed materials on a skylight regulates the building's climate by shielding the interior from high heat loads in summer and letting in sunlight in winter. "In times of climate change and the resulting increase in heat stress, efficient and low-maintenance shading systems such as the 'Solar Gate' realised in the 'livMatS Biomimetic Shell @ FIT' are becoming increasingly important," says Prof.Thomas Speck, Director of the Botanic Garden and member of the spokesperson team of the livMatS Cluster of Excellence at the University of Freiburg. The "solar gate", which passively adapts to solar conditions, is based on a biomimetic principle modelled on pine cones, which open and close in a moisture-controlled manner. "In the future, we will also explore other solutions for designing building facades that can adapt to changing environmental conditions, such as temperature. In this way, we can create a pleasant indoor climate and enable the building to operate in a CO2 neutral manner," says Rühe.

Project Team

Cluster of Excellence IntCDC – Integrative Computational Design and Construction for Architecture, University of Stuttgart.

Institute for Computational Design and Construction (ICD)

Prof. Achim Menges, Felix Amtsberg, Monika Göbel, Hans Jakob Wagner, Laura Kiesewetter, Nils Opgenorth, Christoph Schlopschnat, Tim Stark, Simon Treml, Xiliu Yang (Biomimetic Shell); Dylan Wood, Tiffany Cheng, Ekin Sila Sahin, Yasaman Tahouni (Solar Gate)

Institute of Building Structures and Structural Design (ITKE)

Prof. Dr. Jan Knippers, Simon Bechert

Cluster of Excellence LivMatS - Living, Adaptive and Energy-autonomous Materials Systems, Albert-Ludwigs-Universitat Freiburg

Prof. Dr. Jürgen Ruhe, Prof. Dr. Thomas Speck, Prof. Dr. Anna Fischer

Müllerblaustein Building Structures GmbH, Blaustein

Jochen Friedel, Johannes Groner, Daniel Gold

Project Participants

Research Partners

Cluster of Excellence IntCDC – Integrative Computational Design and Construction for Architecture, University of Stuttgart.

Institute for System Dynamics (ISYS)

Prof. Dr. Oliver Sawodny, Andreas Gienger, Anja Lauer, Sergej Klassen

Institute for Engineering Geodesy (IIGS)

Prof. Dr. Volker Schwieger, Sahar Abolhasani, Laura Balangé

Architectural Computing, Institute for Computational Design and Construction (ICD)

Prof. Dr. Thomas Wortmann, Lior Skoury, Max Zorn

Institute for Acoustics and Building Physics (IABP)

Prof. Dr. Philip Leistner, Roberta di Bari, Rafael Horn

IntCDC Large Scale Construction Laboratory

Dennis Bartl, Sebastian Esser, Sven Hänzka, Hendrik Köhler

Further Project Participants

Expert Contact:

Prof. Achim Menges

Institute for Computational Design and Construction (ICD)

Spokesperson for the Cluster of Excellence Integrative Computational Design and Construction for Architecture (IntCDC)

Phone +49 711/ 685-82786

email

- Detailed project description and a media package

- Project Site livMatS Biomimetic Shell

- Press Information, March 16, 2023: Leibniz Prize awarded to Prof. Achim Menges

Project Participants

Further Consulting Engineers

erdrich wodtke Planungsgesellschaft mbh

Christian Erdrich

Transsolar Energietechnik Gmbh

Prof. Dr. Thomas Auer, Christian Frenzel

Bauphysik 5

Joachim Seyfried

BEC GmbH

Matthias Buck

Belzner Holmes Light-Design, Stuttgart

Thomas Hollubarsc

Project Participants

Approval Procedure

MPA University of Stuttgart

Dr. Simon Aicher

Further Execution

erdrich wodtke Planungsgesellschaft mbh

Geoconsult Ruppenthal

Vermessungsbüro Nutto

IB Becherer

Klitzke ELT-Plan

Prof. Dr.-Ing. Heinrich Bechert + Partner

FW Glashaus Metallbau GmbH & Co. KG

Moser GmbH & Co. KG

Lösch GmbH & Co. KG Lightning protection construction

Parquet Studio Ganter GmbH & Co. KG

Elektro Mutter GmbH

Rees Sanitary and heating installations

Jakober GmbH Kiefer & Sohn GmbH

Dirk Pesec

Project Support

DFG German Research Foundation

Carlisle Construction Materials GmbH

HECO-Schrauben GmbH & Co. KG

Henkel AG & Co. KGaA

Puren GmbH Raimund-Beck KG

Raimund-Beck KG