As a greenhouse gas, carbon dioxide (CO2) has a poor image. Yet, when subject to high pressure, it can absorb an enormous quantity of heat in a very small space, which is why researchers from the University of Stuttgart's Institute of Nuclear Technology and Energy Systems (IKE) want to use it, rather than water, for more compact heat dissipation systems. These could be retrofitted, for example, to nuclear power stations to protect against a core meltdown, or to core-powered power stations to enable a more flexible ramp up and shut down.

Fukushima, 11th of March 2011: a severe earthquake and subsequent tsunami lead to core meltdowns in three nuclear power station reactors. Whilst the fast shutdown trip system does work, which shuts down the nuclear fission reaction, the cooling systems shut down because the power supply is cut and the emergency power supplies are submerged in the flood waters, a “beyond-design-basis event” occurs. The reason was that, even after the reactors are shut down, cooling is still necessary because the existing short-lived fission products continue to decay radioactively for several days, which generates so-called decay heat.

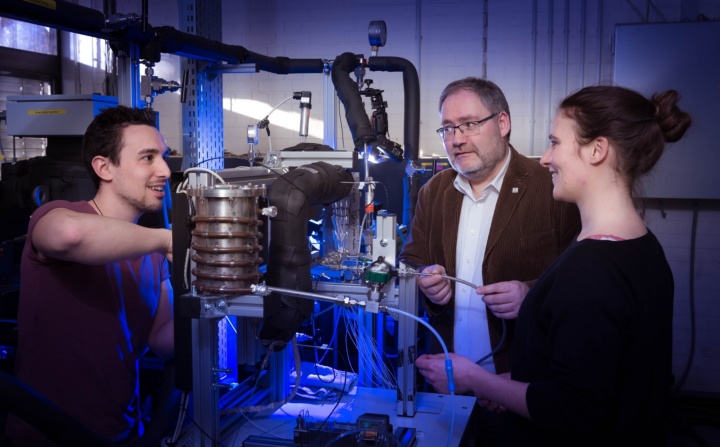

“We could easily retrofit a nuclear power station with a heat dissipation system that would simultaneously use the decay heat to generate electricity, and which would also be very small” says Jörg Starflinger, Director of the IKE. Because systems of this kind generally generate more power than they require for their own operation, they could be used during power outages for such things as recharging emergency power supply batteries. This may have been enough to prevent the reactor catastrophe at Fukushima. Engineers at the IKE are currently collaborating with other partners in the EU project “sCO2-HeRo” (Supercritical CO2 Heat Removal System) to assess the feasibility of this type of retrofittable back-up system for nuclear reactors.

CO2 Instead of Steam

The emergency cooling system developed by the team works in a similar way to the usual steam circuit that drives a turbine to generate electrical power in nuclear and coal-fired power stations – only it uses CO2.

The CO2 is strongly compressed and heated up in the heat exchanger by steam from the reactor, which reaches temperatures in excess of 200 °C. This further increases the CO2 pressure and sets a turbine in rotation, which drives the compressor and a power generator. The CO2 then decompresses back to its starting pressure and cools down. The residual heat is dissipated via a second heat exchanger, the condenser, into the ambient air and the CO2 is pumped back into the compressor to begin a new cycle. The system starts automatically whenever the power cuts out, whereby a valve opens that had previously been held closed by electromagnets, which allows hot steam to flow from the reactor to the heat exchanger through which the CO2 is flowing.

Smaller Than a Lorry Container

“The biggest challenge”, Starflinger explains, “is the lack of space in a nuclear power station”. Therefore, to retrofit one with a heat dissipation system, it would have to be as small as possible. To achieve this, the scientists employ a trick: they use the CO2 above its critical temperature of 31 °C and its critical pressure of 74 bar, which is still around three times lower than that reached in the water-steam circuit. In the supercritical state, there is no longer any difference between the gaseous and liquid forms. Close to the critical point, this supercritical CO2 has the density of a liquid and the toughness of a gas.

What is special about this is that it stores a vast amount of heat in a small space, without heating up strongly, thus its impact on the materials is minimal. Because, in addition, working pressure and the pressure gradient to the turbine are lower, more compact heat exchangers, compressors and turbines can be used than with a water-steam circuit – yet with a similar degree of efficiency. “The system could potentially be accommodated in a lorry container, whereas a water-steam circuit would require an entire hall”, says Starflinger happily. In the SCARLETT research facility at the IKE, his team has been working on the development of a heat exchanger consisting of parallel plates through which steam and supercritical CO2 flow alternatively in a sandwich- like configuration. A living-room-sized part of the CO2 circuit has been set up there.

The biggest challenge is the lack of space in a nuclear power station.

Prof. Jörg Starflinger, IKE, University of Stuttgart

Small-Scale Demonstration System

“Compared with water, I only need one sixth of the heat-exchange surface area to absorb the same amount of heat”, says the reactor safety specialist. The question is, how small can the heat-exchange channels become, without building up too much pressure, which would then be missing at the turbine end? That would, in turn, mean less electrical output. In the meantime, the partners have sent the individual components, which they each developed independently, to the simulation center in Essen, where they have assembled them to build a small-scale demonstration system, where the developers can simulate various faults to test whether the system could function as an emergency back-up system.

Independent of the Heat Source

However, the supercritical CO2 circuit is not restricted to nuclear power stations. In the EU project “sCO2-Flex”, which was launched at the beginning of this year, ten European partners, including the IKE, want to replace the water-steam circuits used for power generation in coal-fuelled power stations. Because the CO2 system is more compact, the coal-fuelled power station could be powered up and down in just a few minutes thus producing more or less electricity depending on the demand. Conventional coal-fuelled power stations can take up to half an hour to reach their maximum performance. “In future, these systems will have to be able to react better to fluctuating feed-in from solar and wind-power systems”, Starflinger explains, going on to say that, the hope is that they could also be built more cost-effectively, as less material is required.

Not a 1:1 Transfer

Although, says Starflinger, the CO2 circuit will be the same, in principle, as for a nuclear power station, it is still not possible to transfer the system on a 1 for 1 basis. All components need to be redesigned and adapted to the much higher temperatures of up to 600 °C, which result from the combustion of coal, as well as to the greater increase in pressure that the absorbed heat will cause within the system.

Two doctoral students at the IKE are currently researching the condensation of supercritical CO2 in the test system with a view to developing a condenser in collaboration with a corporate partner at a later date. “We're primarily interested in how the velocity and orientation of the flow direction affects the thermal transfer and pressure loss close to the critical point” Starflinger explains. The question as to who would even need these systems whenever they are finally ready for market, given the agreed national energy transition policy, elicits nothing but a tired smile from Starflinger. “If not Germany then some other country”, the engineer counters. France, Finland and the United Kingdom, for example, are already planning new nuclear power stations. Altogether, he says, the idea of exploiting supercritical CO2 for power generation is completely independent of the heat source. “One could also consider generating electricity wherever excess heat is produced throughout industry”, Starflinger adds, “for example in the cement and paper industries, or even in solar or bio-mass-fueled power stations”. So, the greenhouse gas, CO2, can also have its uses!

Helmine Braitmaier