The “Integrative Computational Design and Construction for Architecture” Cluster of Excellence (IntCDC) at the University of Stuttgart is aiming to utilize digital methods to make the building industry more effective and save resources. Intelligent construction systems such the “Urbach Tower” are also paving the way for a breathtaking new aesthetics.

As they approach it, the Urbach Tower appears to cyclists on the Rems valley route near Stuttgart as an elegantly curved landmark in the foothills of the Schurwald. But, looking up from the plinth of the observation tower, will take your breath away: 14 meters high, the timber elements spiral skyward completely unsupported, each of them curved in an almost absurd manner and perfectly interlocked with the adjacent panels. Can timber panels be shaped like this?

Yes, they can. However, until now, it has required heavy pressing plant and a lot of energy. In contrast, the panels used in the Urbach Tower deform themselves into a precisely calculated, complex curvature virtually of their own accord – unprecedented anywhere in the world!

Giving timber new functions

The process on which the tower is based was developed collaboratively by the University of Stuttgart’s Institute for Computational Design and Construction (ICD), the ETH Zurich and the Swiss Federal Laboratories for Materials Science and Technology (Empa), and applied together with the University of Stuttgart’s Institute of Building Structures and Structural Design (ITKE). It takes advantage of a characteristic of timber that is actually undesirable, namely warping.

When it dries, damp timber contracts more strongly perpendicular to the direction of grain than along the grain. The researchers exploit this property by laminating two layers of wood such that their grains are oriented differently.

These laminated plates, which are known as “bilayers” form the basic building blocks of the new process. One layer shrinks more than the other when the moisture content in the bilayer decreases. The timber is deformed, because the two layers are firmly glued together. The precise degree of deformation depends on the thickness of the layers, the orientation of the fibers and the moisture content, all of which can be calculated in a computer model. The researchers refer to this process as “timber programming”.

As Dylan Wood, head of the Materials Programming Research Group at the ICD explains, the ingenious use of self-forming makes it possible to give an ancient building material such as timber completely new functions, because curved components have a higher structural capacity than flat ones: “this lends a new perspective to the digital design and manufacture of large timber components with complex geometries”.

Cluster of Excellence for novel concepts in architecture

Thus, this project clearly demonstrates how the use of digital planning, simulation and manufacturing processes can pave the way for a new way of thinking. This is one of the key concerns of the “Integrative Computational Design and Construction for Architecture” Cluster of Excellence (IntCDC) at the University of Stuttgart, which will receive a total of 45.5 million euro in an initial funding phase until 2025 as part of the strategy of excellence for strengthening cutting-edge research in Germany.

The cluster aims to find answers to an alarming development: over the next 35 years, additional urban housing will be required for 2.6 billion people due to population growth and urbanization. However the construction industry is already consuming 40 percent of the world’s resources, which is partly due to the fact that productivity in the construction industry has been stagnating for years. And the spatial requirements continue to increase rapidly.

- The Stuttgart Way

Networked disciplines and interdisciplinary collaboration at the University of Stuttgart

Digital networking of planning and construction

The 22 professors within the cluster are relying on co-design to make construction more innovative and efficient. As Prof. Achim Menges, the cluster spokesman and head of the ICD, explains, the digital networking of planning, construction processes and building systems is key to this: “what we want is to exploit the full potential of digital technologies through an integrative and interdisciplinary research approach, to create the basis for groundbreaking innovations and sustainable planning and construction.”

Two pavilions erected on the grounds of the Federal Horticultural Show (BUGA) in Heilbronn in the summer of 2019, which drew in millions of visitors, also demonstrate this new way of thinking, which has attracted worldwide attention: one is a seven-meter high, extremely material-efficient unsupported timber construction that spans a floor area of 500 m2; the other is an equally high, transparent glass and carbon fiber dome, and was the first ever construction system to be digitally developed throughout.

Learning from biology – understanding natural structures

Such constructions are often inspired by nature: the sand dollar, a subspecies of the sea urchin served as the biological model for the panel structures used in the timber pavilion. The shell structure of the fiber pavilion is based on the wings of a flying beetle. Self-shaping mechanisms are also found, for example, in plants that alter their shapes to release their seeds. “For us”, says Menges, “biology serves as a motivation for scientific lateral thinking”. The challenge for architects is to gain a structural understanding of the principles and functions of nature and to implement them using newly developed materials and tools.

Biology serves as a motivation for scientific lateral thinking.

Prof. Achim Menges

“We’ve developed a new design process in which planning and construction are conceptualized together from the very outset.” It starts with the preparatory software development for novel construction systems and encompasses the robotic production process and simulations aimed at increasing material efficiency to the preparation of new legal standards, for such things as structural stability certification. Such a comprehensive approach can only succeed on an interdisciplinary basis. The IntCDC Cluster of Excellence therefore includes researchers from the fields of architecture, civil engineering, building physics, engineering geodesy, production and systems engineering, computer science and robotics, as well as from the humanities and social sciences.

Robotic prefabrication is an important step en route to a new architecture. The timber pavilion at the BUGA in Heilbronn comprises almost 400 hollow cassette elements, the manufacture of which would have been extremely costly using conventional methods. Instead, the design was implemented at the Müllerblaustein timber construction site near Ulm, Germany in a fully automated production process developed by the ICD, which involved the use of intercommunicating robotic systems, which cut the materials, joined the layers together and milled out the notches where the segments interlock. The deviation in the timber elements is less than two tenths of a millimeter.

The robot used for manufacturing the fiber pavilion, which winds the glass and carbon fiber around anchor points, is located at one University of Stuttgart’s satellite sites in the Wangen district . The fibers are deformed during the winding process, which gives them a curvature after which they harden. This process makes it possible to specifically adapt the geometry and structure of the fibers for each of the 60 components to meet the relevant requirements without the need for molds and without creating any waste.

A house with a twist – smal prototype, major impact

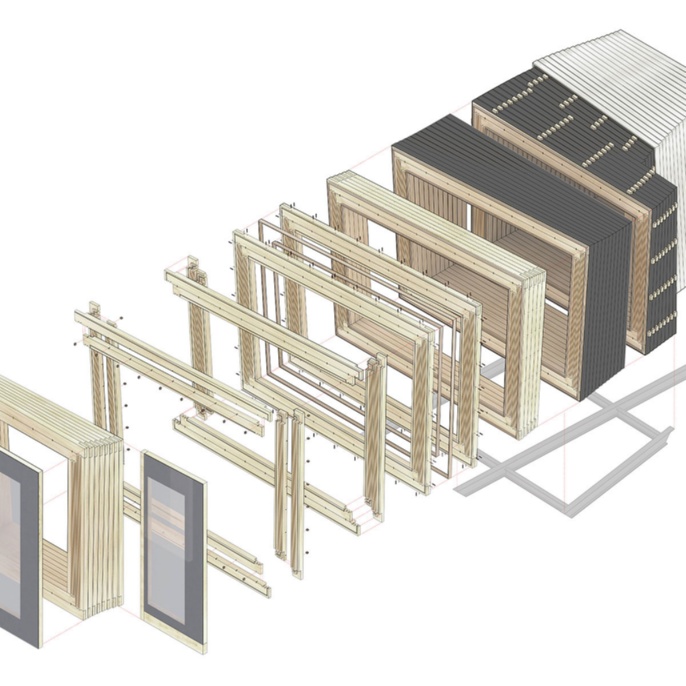

Just what digital design and manufacturing methods can achieve in house construction was demonstrated in the Timber Prototype House, a small, digitally manufactured log cabin at the International Building Exhibition (IBA) 2019 in Thuringia, Germany. Whereas traditional log cabins consist of horizontally stacked logs, the IBA prototype house comprises 440 vertically offset support frames made of squared CNCmilled timber. Intelligent slits in the spruce beams prevent the notorious cracking and increase the insulating properties. A parameterized corner joint is milled into the ends of the timber, which enables the on-site tradesman to simply join the timber frames together with no metal parts or glue.

And, finally, the fully integrated computer-aided design and manufacturing process enables the gentle bending of walls and ceilings. This twist, not only minimizes the materials used to construct the micro-house, but also makes an architectural delight.

Text: Andrea Mayer-Grenu

This article was published in the magazine “forschung leben”.