While miniaturization is already well advanced in electrical engineering, analysis and process technology in medicine and biochemistry still fills entire laboratories. Researchers from the University of Stuttgart and the Center for Free-Electron Laser Science (CFEL) in Hamburg have now developed a method which enables a laboratory to be reduced to the size of the tip of a needle. It manages this thanks to short-pulse lasers, photoresist and 3D printing. The method opens up a new era of biomedical applications, both for formulating medicines as well as for minimally invasive operating techniques. The specialist magazine Nature Communications* has reported on it.

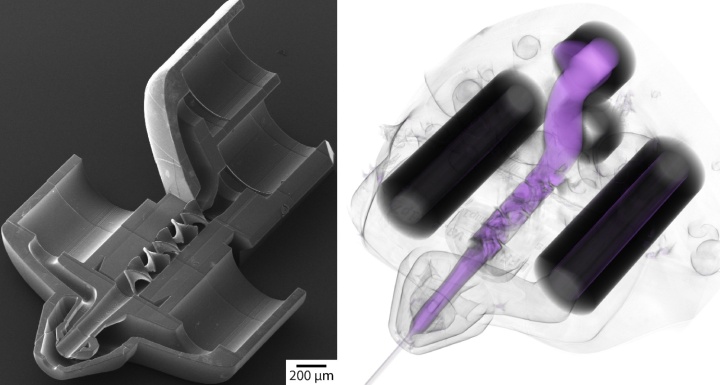

In the last few years, 3D printing has revolutionized the production of complicated shapes. By using serial application, whereby things are written point by point or line by line, even the most complex components can be created quickly and easily. In order to also develop this method for producing a laboratory in miniature, the team of researchers are now manufacturing compact processors for liquids that are hardly any bigger than the tip of a human hair, with the help of a short-pulse laser in combination with an optical photoresist. In the process, integrated circuits for liquids are constructed as a network of very fine channels.

“Traditionally when printing, the different functional parts such as letters were placed side by side on the same level to make a sentence. With our new approach, we have now been able to knot the ‘letters’ together in such a way that ink without any gaps is almost the only thing that’s left over”, explains project leader Junior Professor Michael Heymann, who has led the Intelligent Biointegrative Systems group at the Institute of Biomaterials and Biomolecular Systems at the University of Stuttgart since October 2019. He said it was particularly difficult to validate the desired function of the prototypes. “It’s like when you want to read a newspaper that has been folded up.” Therefore, to read the intricately knotted response networks the team works together with experts in X-ray tomography at the DESY in Hamburg and at the Paul Scherrer Institute in Switzerland. They have a new magnifying glass, which does more than just remagnify the response networks but can also straighten out the text nodes into a readable page again at the same time.

X-ray flashes through a tiny jet of water

The high level of precision of the new production process makes it possible for the team to optimize special nozzles for the spatial structural resolution of biological molecules. To do this, the researchers created a jet of water less than a thousandth of a millimeter in diameter to illuminate the biological molecules with X-ray flashes. The atomic architecture of the biological molecules can be calculated with a high degree of accuracy using a series of images. In addition, the researchers succeeded in optimizing particularly efficient mixers, meaning controlled biochemical reactions can be initiated. The team plans to use these to record serial snapshots of biochemical reaction processes between enzymes and their substrates. The X-ray laser can be used as a kind of film camera in order to better understand molecular dynamics, such as the interaction between a medical compound and the target protein.

Wide range of applications in medicine

The highly miniaturized nozzles and mixers also make a range of entirely new biomedical applications possible. For example, the technology can be used to produce wafer-thin flexible endoscopes, which can carry out operations and investigations in the smallest of openings in the body or in machines. Likewise, the formulation of medicines can also be improved. For example, it is still difficult from a technical perspective to optimally spray substances for asthma patients. With standard inhalers, only a very small amount of the substance actually gets into the patient’s lungs. The compact 3D nozzles should make it possible to spray evenly and so reduce unwanted side-effects, even in chronic patients.

Expert Contact:

Junior Professor. Michael Heymann, University of Stuttgart, Institute of Biomaterials and Biomolecular Systems, Tel.: +49 (0)711/685 61686, Email

Original publication*: Knoska, et al., M. Heymann: Ultracompact 3D microfluidics for time-resolved structural biology, Nature Communications, (2020); DOI: 10.1038/s41467-020-14434-6,