46 million tons of CO 2 emissions were accounted for by the chemical-pharmaceutical industry in Germany in 2012. Scientists from the University of Stuttgart, the German Aerospace Centre as well as Plinke (Bad Homburg) want to convert greenhouse gas into formic acid with the help of renewable energies and to use this for energy storage.

The discussion as to how the European climate goals (20% fewer greenhouse gas emissions, 20% more energy efficiency, 20% renewable energies) can be achieved by 2020 mostly revolves around the fields of energy and transport. But also smaller sectors like the chemical-pharmaceutical industry can make a considerable contribution in order to reduce the carbon footprint.

In addition CO 2 is an easily accessible source of carbon at chemical sites that can be used as a raw material for various chemical products, thereby reducing the dependence on oil, gas and biomass imports. One of these products is widespread formic acid. This is used for example in the manufacturing of textiles and leather goods. Its production, however, also offers the specific possibility of storing surplus electrical power in a chemical form. As soon as there is in turn a need for electrical power, the formic acid can easily be broken down into hydrogen and CO 2 and the arising carbon can be converted back into electricity, for example in a fuel cell.

Scientists at the Institute of Technical Chemistry at the University of Stuttgart, the German Aerospace Centre (Stuttgart location) as well as Plinke (Bad Homburg) have now got together in order to research an energy-efficient electrochemical method to manufacture formic acid from CO 2 emissions. The goal of the project sponsored by the Federal Ministry of Economics and Technology with a sum of 1.5 million Euros and entitled “Energy-Efficient Electrochemistry in the Micro-Reactor 2.0” (EnEIMi 2.0) is to use regenerative energies for this purpose, such as photovoltaic or wind energy and at the same time to develop a storage medium for these energies. “ With this the project not only makes a small contribution to achieve the climate targets but in particular also puts the turnaround in energy policy into practice, that is heavily reliant on new storage technologies”, said Professor Elias Klemm, Head of the Institute of Technical Chemistry at the University of Stuttgart and Project Coordinator of EnEIMi 2.0.

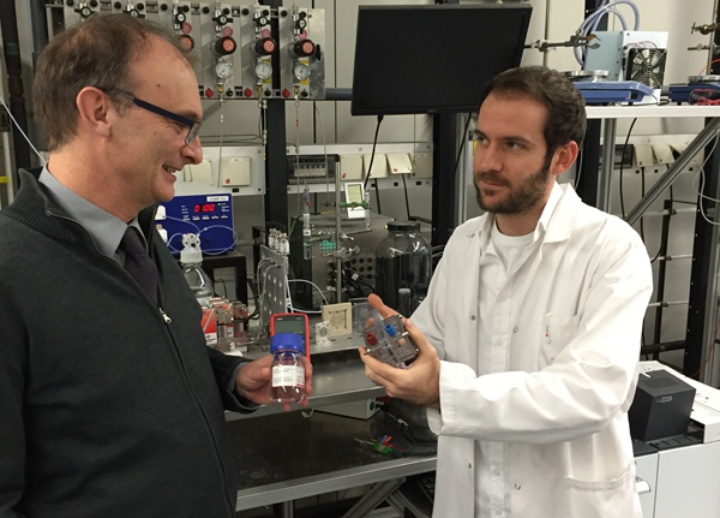

The electrochemical conversion of CO 2 into formic acid is to take place in micro-reactors, making the process particularly energy-efficient. The scientists from Stuttgart have already described the technical feasibility of this type of process, as well as concepts for the reactors in a previous project. In the further course of the project the scientists will rely on a reactor assembly made of acrylic glass (polymethylmethacrylate) with which almost 1.5 kg CO 2 per hour and square meter electrode area can already be converted, corresponding to a current density of 200 milliampere per square centimeter (mA/cm 2).

A great optimization potential still exists in the manufacturing and development of the used electrodes and the catalysts contained therein in which the CO 2 is converted to formic acid. Special attention should be paid to this in a subsequent project since they decide how much CO 2 can be converted in the reactor and how efficiently this can be done. Since the process is able to create an economic solution for the utilization of CO 2, it is also of particularly interest for the small and medium-sized enterprises that constitute the great majority in the chemical-pharmaceutical industry. A container system is to be developed with Plinke in the course of the project that can be tested on potential customers in a mobile and flexible way.

Further information:

Professor Dr. Elias Klemm, University of Stuttgart, Institute of Technical Chemistry, Tel.: 0711/685 64059, Email: elias.klemm@itc.uni-stuttgart.de.

D. Kopljar, A. Inan, P. Vindayer, R. Scholz, N. Frangos, N. Wagner, E. Klemm, Development and Use of Gas Diffusion Electrodes for the electrochemical reduction of CO2, Chem. Ing. Tech. 2015, 87, 855., http://onlinelibrary.wiley.com/doi/10.1002/cite.201400135/full

The project is funded in the framework of the 6th Energy Research Program of the Federal Government by the Federal Ministry of Economics and Technology under the funding code 03ET1379A, B, C.