Whether thermal insulation in winter or heat protection in summer: there is an increasing demand for materials for insulation and waterproofing. Rising energy prices as well as government measures to save energy and avoid climate-damaging greenhouse gases are fueling this development. Global consumption of insulating material is expected to total up to 579 million cubic meters by 2025, with Europe alone accounting for more than 200 million cubic meters.

Plastic foams such as polystyrene insulation boards are a widely used and well-insulating material. However, many plastic foams are flammable. In the case of several major fires in the recent past, such as at the Grenfell Tower in London, it is suspected that the fire was able to spread massively within a few minutes, partly because of the façade insulation. Moreover, plastic foams are also ecologically controversial because they are produced on the basis of petroleum, are not biodegradable, and can only be recycled with high energy expenditure.

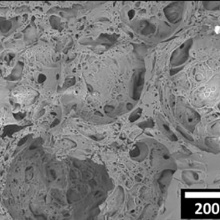

The teams led by Prof. Cosima Stubenrauch from the Institute of Physical Chemistry at the University of Stuttgart and Prof. Helmut Cölfen from the Institute of Physical Chemistry at the University of Konstanz have developed a new mineral plastic foam that is designed as a bio-inspired hybrid material and does not have any of the aforementioned disadvantages of plastic foams. The researchers mixed a sodium carbonate solution with a solution of polyacrylic acid and calcium chloride, foamed it, and then gelled the mixture. The intermediate product is a hydrogel, a polymer network swollen with water, like Jell-O, for example. The hydrogel that is produced can be molded into any shape. By hardening the hydrogel, a porous mineral plastic foam is obtained which retains the shape of the hydrogel.

The mineral plastic foam is five to six times harder than conventional acrylic glass, but still easy to process. Due to its mineral portion of up to more than 30 percent by mass, it is not flammable, unlike purely organic polymers such as polyethylene (PE). The constituents calcium, calcium carbonate, and polyacrylic acid are harmless to health and are also used in eye drops and eye gels, for example. The mineral plastic foam can be completely dissolved in many conventional acids, which enables simple and efficient recycling.

A patent application is currently being filed for the mineral plastic (DE 102020002914). Through the patent brokerage firm Technologie-Lizenz-Buero of the Baden-Wuerttemberg Universities (TLB), the researchers are now looking for industrial partners that are able to produce mineral plastic foams on a large scale in order to sell them commercially.

| Contact | Prof. Dr. Cosima Stubenrauch, Philipp Menold, University of Stuttgart, Institute of Physical Chemistry Phone +49-(0)711-685-64470, -64481, E-Mail: cosima.stubenrauch@ipc.uni-stuttgart.de, mailto:philipp.menold@ipc.uni-stuttgart.de |

|---|