Mario Stoll (right) and Nino Dakov are both research assistants at the University of Stuttgart’s Institute of Machine Components (IMA). The both completed their Master’s degrees in mechanical engineering at the University of Stuttgart and are currently working on their PhDs. And they have made an exciting discovery, which began one evening when they were talking to colleagues at the institute. The invention has since been registered with the patent office and the two young scientists are in close contact with renowned companies in the sealing sector.

A sealing ring for rotating systems

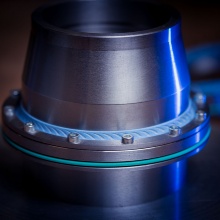

The invention is a new type of sealing ring for rotating systems. This type of sealing ring is used in vehicles, for example in the transmission or on the crankshaft – a mass-produced product. In the engine, the crankshaft sealing ring has to fit so tight that the oil cannot leak from the engine, but the shaft must still be able to turn. The best available solution is a radial shaft seal made of elastomer that is constructed so that it barely comes into contact with the shaft. A small pump motion ensures that any oil that leaks during operation is moved back to the engine. However, this type of radial shaft seal is not very durable if it comes into contact with heat or chemicals.

First new innovation for decades

Over the last few decades, there has been little in the way of new design innovations in the sealing ring sector. Several years ago, seal technology specialist Lothar Hörl, engineer at IMA, came up with a new idea for designing seals. The two young scientists are now revisiting this idea with his help.

This new type of seal is made of the fluoroplastic PTFE, also known as Teflon and tiny structuring strips have been added to the back of the ring. When the seal is attached to the shaft, it is unevenly stretched by the shaft circumference and only the spaces between the structuring strips touch the shaft. This create thin channels that generate a small pumping effect.

Zero leakage

Mario Stoll and Nino Dakov have already extensively tested the seals. They first put oil on the outer edge of the experimental set-up and waited to see what would happen. The oil was sucked through the channels back inside and disappeared. “We didn’t expect such clear results during the first test”, says Mario Stoll. The new seal was then tested under real-life conditions with a high rotational speed and then underwent a 1,000-hour test. It performed excellently in both tests.

The invention is attracting a lot of attention in the industry

In December 2016, the two scientists registered the rear-structured sealing ring with the patent office, first nationally and then internationally. In spring 2017, they successfully applied for 35,000 euros of funding from the WTT. They used this to buy materials and for prototypes, as well as covering personal costs. They then approached large companies with the prototypes and gained a lot of positive attention, “and not only at the specialist level, managers were also impressed”. At an international congress in Manchester in March, the engineers attracted attention with their new invention and were awarded a prize for the innovation.

Good advice is a great help

The two are pleased that their invention has gained so much attention: “It is a new situation for us. The rules changes when you want to market something”. The advice we were given by the patent attorney, the research department at Division I and the project support we received from Vice Rector Thomas Graf were extremely helpful, say the two engineers.

“You can see how interested companies in the industry are by the number of companies that are currently testing the ring. We are proud that they are willing to test the idea”, say Mario Stoll and Nino Dakov. If everything goes well, one of the companies will buy the license for the new sealing rings from the university.

Mario Stoll

Wissenschaftlicher Mitarbeiter am Institut für Maschinenelemente

Nino Dakov

Wissenschaftlicher Mitarbeiter am Institut für Maschinenelemente