The ARENA2036 focus project “Digital reconfigurable manufacturing of fiber composite components in a resilient production environment” (DIREKT) was established at the start of 2020. It is part of the BMBF funding measure “Internationalization of Leading-Edge Clusters, Forward-Looking Projects and Comparable Networks” (InterSpiN). The Stuttgart Media University (HdM), Balluff GmbH and CIKONI GmbH, a specialist in innovative fiber composite solutions, is also involved in the project alongside the Institute of Aircraft Design (IFB) from the University of Stuttgart.

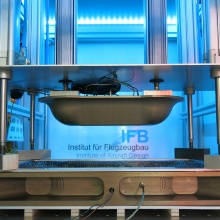

The aim of DIREKT is to develop a reconfigurable, self-monitoring and sensor-supported production environment for components made from high-performance fiber composites. This is done by using fuel-efficient lay-up methods for carbon fiber-based semi-finished products as well as shape-adaptive tools that remove the need to manufacture component-specific molding tools, which can be expensive and is time-consuming. The IFB has integrated a range of sensors into the production environment to continuously monitor the process. This makes it possible to intervene at an early stage, which is supported by a production-related data analysis carried out close to the production site (edge computing).

Reducing product costs and customer-specific component geometries

Scientists expect the combination of digital production technology and shape-adaptive and automated production processes will result in lower costs when producing small and medium quantities. As a result, it will be possible to implement customer-specific component geometries and the lightweight material CFRP (carbon fiber reinforced plastic) in a variety of applications. In order to make the production process more resilient, the pilot production environment built into DIREKT is being digitalized by the InterSpiN partner project I4Production (Implementation of a Cognitive Digital Twin on the Way to Resilient Production) and connected to the virtual environment through the sensor technology incorporated within it. This partner project is another focus project from ARENA 2036, which began in October 2020 and focuses on monitoring production in real time in order to be able to react robustly to disturbances and thus always work in an optimal range. As part of the project, digital twins are being created of the production areas at DIREKT and the GIL project (Global Innovation Linkage) at the Swinburne University of Technology in Melbourne, Australia.

New I4.0 test lab for the production of composite materials

As well as the cooperation in the two projects, which have both been awarded two million euros in funding from the BMBF over a period of three years, another focus of InterSpiN is on scientific exchange with the GIL project and its partners in Australia. This project has a total budget of 3.6 million Australian dollars, and focuses on the automated Industry 4.0 production of fiber composite components in large quantities. As part of the project, the new I4.0 test laboratory will be set up by mid-2021 in cooperation with the Australian national science agency CSIRO (Commonwealth Scientific and Industrial Research Organisation) – a facility for innovative research into the production of composite materials. As well as sharing information and project results, Prof. Fox from the Swinburne University of Technology and Prof. Middendorf from the IFB are also jointly supervising five doctoral researchers.

Expert contact:

Michael Liebl, M.Sc., Institute of Aircraft Design (IFB)

E-Mail