To support hospitals and medical practices that are in direct contact with Covid19 patients, researchers at the University of Stuttgart are making use of existing production capacities to manufacture new face shields using 3D printers. Scientists at the ARENA2036 research campus and the neighboring institutes on the Vaihingen campus of the University of Stuttgart are making use of available facilities that are typically used for the construction of prototypes for automotive, aerospace, and engineering applications.

The current focus is on face shields, whose mounts can be produced using 3D printers. The first prototypes have already been made available to the Klinikum am Steinenberg (clinical center in Reutlingen), the Diakonie-Klinikum (Protestant clinical center in Stuttgart), and the Robert Bosch Hospital. In close cooperation with the hospital staff, the researchers continually improve the design of the face shields. 3D printing modules are available for download on the Corona website of ARENA2036 [de]. Through the partner network of ARENA2036, the university was able to quickly find industrial partners who support the initiative with great commitment and enable rapid scalability of production.

Prof. Wolfram Ressel, Rector of the University of Stuttgart, recognized the initiative as an act of the university’s solidarity with the health care system in the region and said: “In the past few days we have seen all members of the university come together in this time of crisis and help tackle the problems we will have to solve especially in the upcoming summer semester. Above all, the fact that our forces and commitment are being mobilized to make a contribution to society with our expertise in these challenging times fills me with gratitude.”

Initiated by the ARENA2036 research campus and the Institute of Aircraft Design (IFB) at the University of Stuttgart, requests for more than 1000 face shields were received from hospitals and medical practices in the region within a short time. So far, feedback on the face shields has been very positive. The researchers are in close contact with hospitals and clinical centers in the region, including the Robert Bosch Hospital, the Diakonie-Klinikum, the Marienhospital, the Klinikum Ludwigsburg, and the Kreiskliniken Reutlingen. The flexibility of the manufacturing processes used enables rapid iteration of different prototypes and the adjustment based on the experience of hospital staff from practice.

Besides the University of Stuttgart, numerous industrial and research partners from the region are involved at the research campus and, like TRUMPF GmbH + Co. KG, have also offered their active support. Intended as a joint project between research and industry right from the start, the initiative enables, if required, a significant increase in production capacities by using further manufacturing techniques such as injection molding or laser cutting.

At the University of Stuttgart, the commitment in times of the corona crisis is on a voluntary basis. Therefore, Dr.-Ing. Frieder Heieck, Research Coordinator of ARENA2036, and the research group led by Prof. Peter Middendorf, Head of the Institute of Aircraft Design and Vice Rector for Knowledge and Technology Transfer at the University of Stuttgart, point out that the manufacture of medical technology products takes place in close coordination with clinical centers and hospital groups. Necessary measures for disinfecting the shields in accordance with hygiene standards during manufacture and delivery are taken in consultation with the hospitals involved.

Information on the developed face shield

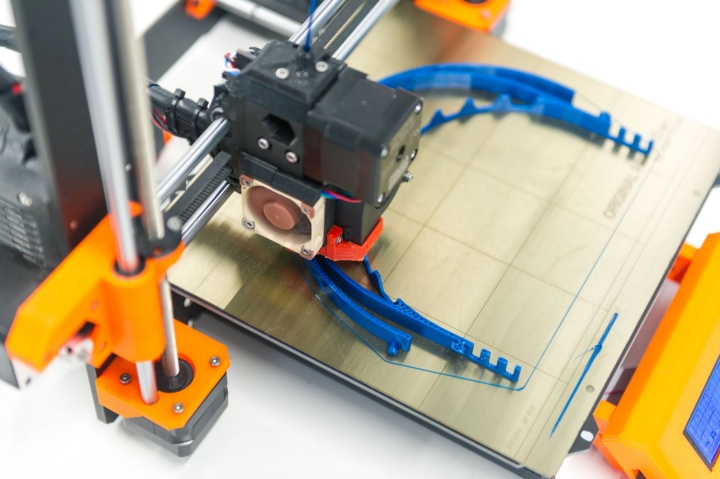

There are now numerous design proposals for 3D-printable face shields on the internet. The design used at the University of Stuttgart is based on a proposal by the Czech company Prusa Research, which was developed in consultation with the Czech Ministry of Health. The University of Stuttgart and the ARENA2036 research campus have also been using the 3D printers from Prusa Research for several years. The resulting new design, which was improved in cooperation with a hospital in Reutlingen, has an enlarged visor area and additional features to better meet the requirements of clinical routine.

The face shield consists of a head mount made of technical plastics (e.g. PETG, ABS) or similar materials. The visor itself is made of a transparent film that can be cut automatically using a plotter or a laser. An elastic band is attached to the mount for fixation. The band’s material and design are currently being developed in coordination with the hospitals with regard to wearing comfort and suitability for disinfection.

There are also designs available that use A4 transparent films to quickly increase the number of items. The corresponding head mounts are simpler and are already being produced on laser cutting systems from the Trumpf company in Ditzingen. This means that more than 100 mounts can be produced per hour, which the helpers then assemble in the ARENA2036 and prepare for distribution. The semi-finished products for this purpose were provided by the company Ensinger GmbH in Nufringen.

Information on the financing

The face shields are manufactured on a voluntary basis by employees of ARENA2036, the University of Stuttgart, as well as partner companies and research institutions. Until further notice, the products can be made available free of charge to hospitals and medical practices that have an acute need. However, the team would be pleased to receive donations in the form of material supply (such as material for the face shield, 3D-printing material, cardboard boxes for delivery). For this purpose the team has set up a donation box at the parking lot at the back of the ARENA2036 building. There, parts can be put in at any time, which the team then takes out and disinfects.

Request and provision of face shields

If you would like to order face shields, please contact the project coordination at ARENA2036 by sending an email. Please provide the following information:

- Name of clinic / clinical center / hospital

- Contact person with phone number for delivery

- Number of face shields required

- We would be happy about feedback & suggestions for improvement regarding design (wearing comfort, protective function, practicality), suitability for disinfection, and arising problems

Expert Contact:

Dr.-Ing. Frieder Heieck, ARENA2036, E-Mail.