At the world's most important industrial trade fair, the University of Stuttgart will present its cutting-edge research from the two Clusters of Excellence “Data-Integrated Simulation Science” and “Integrative Computational Design and Construction for Architecture”. Further exhibits show the pioneering research results in the areas of autonomous systems, biomedical systems, mobility concepts and sealing technology of the future.

The trade fair appearance of the University of Stuttgart at the world's largest industrial exhibition will take place from 1 to 5 April. The exhibition sector for research, development and technology transfer “Research & Technology” shows visionary products and applications and, as a major attraction of the Hanover Fair, brings together representatives from science, industry and politics.

The transfer of knowledge and technology is of central importance at the University of Stuttgart. Not only does the university promote the use of research findings in practice, it also uses its innovations to contribute towards ensuring competitiveness, the capacity for self-reflection, and the well-being of economy and society. Its top achievements are both in basic and in applied research. Prof. Wolfram Ressel, Rector at the University of Stuttgart, points out: “The University of Stuttgart is an innovative, reliable and internationally recognized partner for knowledge and technology transfer in science as well as in industry and society. It is one of our strategic objectives to give our industrial partners access to our research services as efficiently as possible.“

Through this knowledge transfer, the university wants to shape the future of our society responsibly. The vision of the University of Stuttgart “Intelligent Systems for a Sustainable Society” emphasizes this responsibility.

Exhibitors and exhibits of the University of Stuttgart

As co-exhibitors at the “Baden-Wuerttemberg joint stand” organized by Baden-Wuerttemberg International (bw-i), the state’s competence center for the internationalization of business, science and research, scientists from the university will again present exhibits of their cutting-edge research to the visiting public from all over the world.

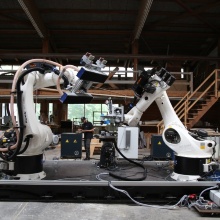

Institute for Computational Design and Building Construction

For the past ten years, the Institute for Computational Design and Building Construction (ICD) at the University of Stuttgart, together with interdisciplinary partners, has been doing research on how digital design tools and robotic manufacturing methods can enable completely new types of building systems. This research is now being deepened and intensified in the Cluster of Excellence “Integrative Computational Design and Construction for Architecture”. One area of specialization is on the development of new processes in timber construction, which are tested together with industrial partners within the framework of demonstrator structures. At the exhibition stand, you will find the Mobile Robotic Timber Manufacturing Platform (TIM). This is a robotic timber manufacturing platform that has been newly developed in a research cooperation between the University of Stuttgart and BEC GmbH. The platform is portable, extensible and modular. It allows a flowing change of additive joining processes such as gripping, placing, nailing or gluing and also milling. TIM is designed for the fully automated (pre-)production of complex wooden structures and in the first application produces 376 individual lightweight cassette segments for the wooden pavilion at the national garden show Bundesgartenschau 2019. Further information (in German)

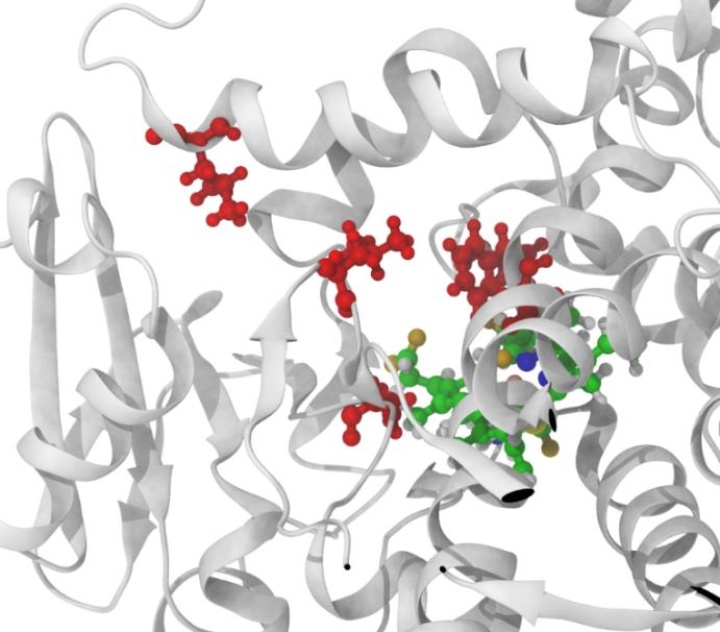

Candidum TGU

The start-up Candidum TGU, which was established at the University of Stuttgart, is working on a computer-assisted enzyme design. When filling washing powder into your washing machine, you rarely think of the technical enzymes that efficiently and in a highly specific way remove fat molecules from textiles. Candidum explores how the genetic blueprint of these enzymes can be modified specifically to achieve even better results. The problem with optimizing the enzymes is the long duration of the process and the high costs that arise. Therefore, Candidum TGU is creating an enzyme database with several million entries that informs about functional properties. From this, a new template for the simulation-based enzyme design can be developed. In this way, the Stuttgart start-up wants to develop more efficient enzymes with the desired properties than was previously possible. At the Hanover Fair, Candidum will be showing visualized structures and simulations of enzymes. The start-up originated from the Cluster of Excellence “Data-Integrated Simulation Science” (SimTech) at the University of Stuttgart. The Cluster of Excellence, sponsored since January 1, 2019, aims at a new category of modeling and calculation methods, given the many data available today from various sources. These take the applicability and accuracy of simulations, as well as the reliability of the decisions based on them, to a new level, thereby introducing a paradigm shift in simulation science. Further information (in German)

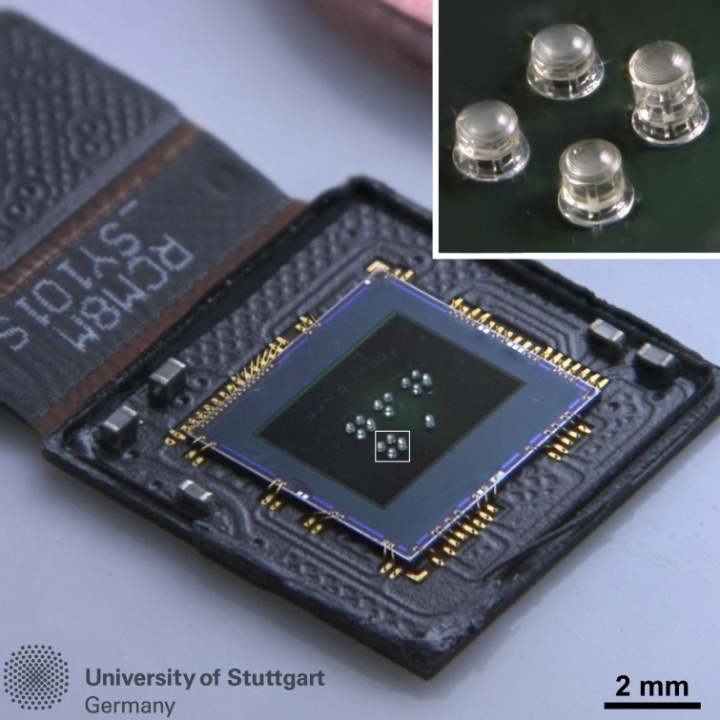

Biomedical Systems

As part of the university’s internal association “Stuttgart Research Center of Photonic Engineering” (SCoPE), the Institute of Applied Optics and the Institute of Physics (4) of the University of Stuttgart are doing research on the miniature optics of the future. The exhibit at the Hanover Fair will show highly miniaturized optical systems. What is special about them is that they are printed directly onto an image sensor and can be individually adapted to different requirements. This enables the production of the smallest bionically inspired camera systems such as compound-eye cameras or cameras with a hundred percent visual acuity. With the help of the 3D printer, lighting and projection systems can also be integrated. These highly miniaturized optical systems are used, among other things, in the areas of optics and endoscopy. Consumers also benefit from this, for example, through better cameras. Further information (in German)

GreenTeam Driverless

Every year, about twenty students of the Green Team at the University of Stuttgart design and manufacture an autonomously driving race car. The highlight of each season are the well-known international Formula Student Competitions. There, also the Green Team of the University of Stuttgart compete with student teams from all over the world on the racetrack. At the trade fair, the students will be presenting an autonomous vehicle. At the heart of the race car are the algorithms, which first recognize the environment of the vehicle, calculate the desired course from there, and then control the vehicle safely and independently on the racetrack. A special brake system ensures that it can stop at any time. Further information (in German)

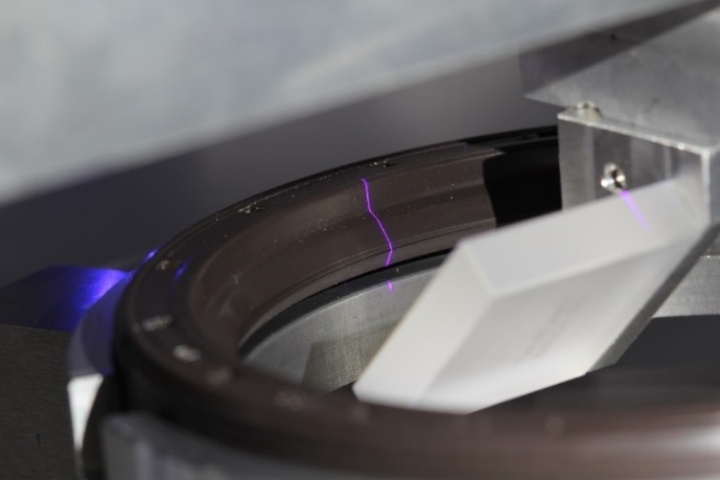

Institute of Machine Components

For more than five decades, the Institute of Machine Components (IMA) has been conducting intensive research on static and dynamic seals. During this time, it has established a nationally and internationally recognized reputation as a neutral and reliable expert in the field of sealing technology. The IMA will be showing trade fair visitors complex matters relating to sealing technology in a way that is vivid and comprehensible to laypeople. The centerpiece is a measuring device developed at the institute for wear measurement on radial shaft seals and hydraulic rod seals. The patented IMA seal scanner captures geometric characteristics on the sealing ring and directly calculates the wear behavior. In addition, the IMA will be exhibiting the patent-pending back-structured shaft seal (B3S) as well as other application examples and models. Further information (in German)

ARENA2036

ARENA2036 is the world's largest research campus for the hardware-based knowledge work in the field of mobility and production of the future. The aim is to generate potentially disruptive and leap innovations, to transfer them to industry and to contribute to the active shaping of the work, mobility and production of the future in the context of digitalization. The direct transfer of research results to industrial applications is intended to increase the competitiveness of Germany as a business location, thereby creating new business models especially for small and medium-sized enterprises. Visitors to the fair will have the opportunity to see a rolling chassis on site. This chassis is the basis for the cyber-physical vehicles of the future. The aim of the researchers is, based on the rolling chassis, to design a vehicle concept that incorporates the innovation process and thus redefines the system boundaries of the product. The exhibit is based on the work of the joint project LeiFu and will be further developed as part of the follow-up project FlexCAR. Further information (in German)