A proposal in the fight against global climate change is to separate CO2 from the waste gases from power plants or factories and to store it deep underground. Natural gas and other gases could also be stored temporarily in the ground in order to buffer fluctuations in the renewable energies. In order for the gases to remain in the ground in the long term, even in the case of unforeseen incidents, sealing technologies, such as biomineralisation, are applied as precautionary measures. Scientists at the Chair for Hydromechanics and Modelling of Hydrosystems at the University of Stuttgart want to improve these technologies in a new research project.

In order to implement the internationally agreed climate targets, CO2-separation and storage will probably be indispensable in the near future, in particular for the major producers of greenhouse gas, like for example coal-fired power stationsIn order to implement the internationally agreed climate targets, CO2-separation and storage will probably be indispensable in the near future, in particular for the major producers of greenhouse gas, like for example coal-fired power stations or in cement production. Gas as an energy source will also probably have to be stored underground for the optimum use of the renewable energies in order to buffer fluctuations when required and when generating renewable energies. Ideal for this are storage reservoirs that are separated from overlying stones or ground water pipes by impermeable top layers. However, CO2 can only be stored from a minimum depth of around 800 metres; in the case of natural gas or synthetic gases shallower depths are sufficient.

The detailed geological features of potential storage formations, however, often cannot be estimated with high accuracy. Therefore, in spite of all due care taken, it is possible that gases can be emitted from a storage facility at unseen weak points or through mechanical or geochemical processes during the injection of gases. Such leakages indeed occur only rarely; however they reduce the efficiency of the process. In order to prevent these, targeted sealing technologies, such as for instance cement injections or biomineralisation, are used.

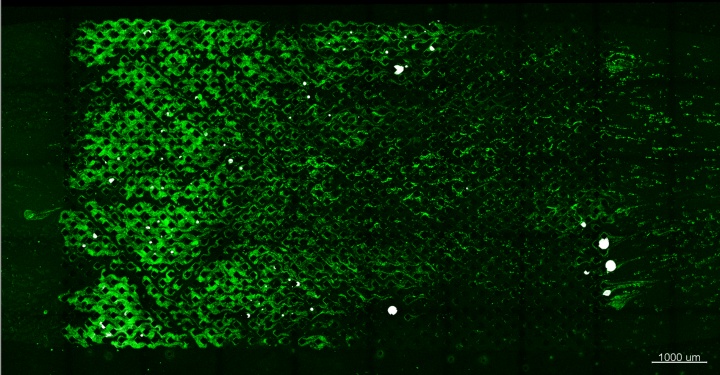

The latter includes the microbiologically induced calcite precipitation (MICP). In this already established process calcium carbonate, a natural, cement-like mineral, is produced by bacteria inserted into the areas to be sealed in a targeted way and other materials deep underground. Due to the low viscosity of the watery solutions used here and the small size of the bacteria, rather large areas can be sealed using this process and also small pores effectively sealed off.

Successful model concept is being developed further

In recent years scientists at the Chair for Hydromechanics and Modelling of Hydrosystems at the University of Stuttgart have developed and successfully tested a complex numerical model concept for this biomineralisation method. In the framework of the new project funded by the German Research Foundation (DFG) with a sum of 268,300 Euros called “Enhancement of model concepts for technically controlled calcite precipitation with particular emphasis on several driving processes, the temperature influence and the two-phase flow“ this model is now to be developed further. In this respect the scientists are looking for ways to be able to apply the MICP method in deeper layers of earth as well. This has not been possible up to now since the soil temperature increases with the depth and the most effective bacteria are only capable of surviving up to a temperature of 45° degrees.

Partners at Montana State University in Bozeman, USA, are experimenting with alternative processes in which the function of the bacteria is taken over by the enzyme urease or by the soil temperature itself. In order to better understand these methods as well, the effects of high temperatures respectively the enzyme are to be included in the model and simulated. The aim is a numerical biomineralisation model that illustrates the various methods of induced calcite precipitation (ICP).

Flow states in focus

Furthermore, the scientists are turning their attention to the flow states in such gas storage facilities. Since water and gas only mix to a limited extent, this leads to capillary effects like those that can be observed when absorbing water in a sponge. Likewise both phases can mutually block each other: if a pore is filled with water, the gas has to find a roundabout way or repress the water. Which path the fluids actually take depends on their features but also on the characteristics of the solid materials. The latter changes in the course of the precipitation since an increasing amount of calcium carbonate is enriched and with this the pore geometry and the mineral composition is changed at the surface. These effects should also be taken into account in the enhanced model and the parameters determined in experiments in order to be able to plan and assess the effect of an ICP application precisely.

Expert Contact:

Johannes Hommel, University of Stuttgart, Chair for Hydromechanics and Modelling of Hydro Systems, Tel.: 0711/685 64600, Email