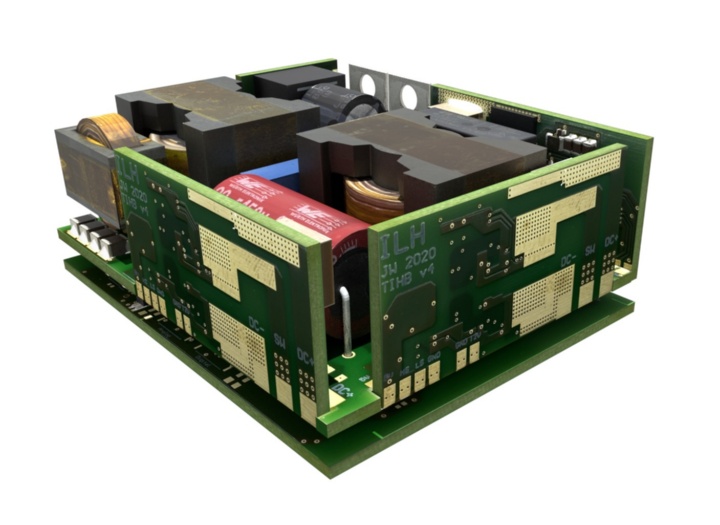

E-mobility shapes the life of more and more people, and e-bikes and e-scooters play an essential role in it. The employed rechargeable batteries become smaller and lighter, the efficiency of the electrified drive train and the cruising range increase. The battery chargers, however, struggle to keep pace with this development. Scientists at the Institute of Robust Power Semiconductor Systems (ILH) and the Institute of Power Electronics and Electrical Drives (ILEA) at the University of Stuttgart have now developed a charger for e-bikes and e-scooters, which sets new standards in terms of power and compactness.

A stronger battery, along with shorter charging times and chargers which are lighter and don’t take up space in your rucksack – such is the dream of every e-biker. To bring it to life scientists at ILH and ILEA have developed the prototype of a plug-integrated charger in the frame of a joint R&D project. In a first step commercially available chargers for e-bikes and e-scooters were analyzed, characterized, investigated and compared to e.g. laptop chargers.

Topologies of the power electronic integrated circuits of a battery charger were compared to decide on the most suitable choice for the target application. The challenge faced: chargers for rechargeable batteries, in contrast to conventional mains power supplies, have to cover a wide range of operating conditions. Thus, the state-of-charge has to impose different voltages and currents, in order to obtain the fastest but also a lifetime-preserving charging process. This imposes stringent requirements on the electrical circuitry, which should be as small but also as power-efficient as possible.

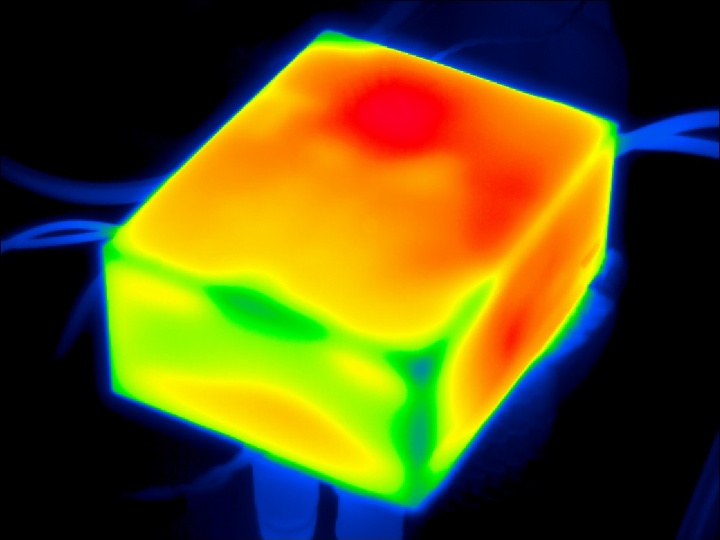

Avoiding Performance Loss through Hotspots

During operation the charger must not exceed certain maximum temperatures on its entire surface. What’s more, it must be fully contained in the housing – hence it is only cooled through passive convection. Under these frame conditions, the efficiency of the charger’s electrical circuits, which have to convert the single-phase ac voltage from the socket outlet into a dc voltage, must be computed by complex three-dimensional simulations. The placement of the components is optimized to ensure an ideal surface temperature distribution but also to ensure electrical integrity and avoid electro-magnetic interferences.

GaN as Game Changer in Power Electronics

To date the semiconductor devices in the voltage converters of commercially available chargers are built from silicon. In R&D the material gallium-nitride (GaN) has been attracting a lot of attention for a few years now. Only recently, the first chargers for mobile phones have become available which use chips made from GaN and promise high power (up to 120 W) at small volume. The devices offer significant advantages in nearly all relevant parameters, but they must first be controlled in the application at high power levels.

The scientists in Stuttgart embraced this challenge and built six custom-designed power stages based on GaN into their prototype. To achieve reliable operation of the highly integrated boards solid knowledge of the technology and comprehensive electrical and mechanical simulations are required. The final prototype of the two institutes reached the target specifications: at the same power rating (more than 150 W) it is about half the size of commercially available chargers, corresponding to a power density of 1.6 W/litre.

Expert Contact:

Prof. Dr. Ingmar Kallfass, University of Stuttgart, Institute of Robust Power Semiconductor Systems, phone +49 (0)711-685-68747, E-Mail