Bipolar plates (BPP) are a key component of modern fuel cells and are therefore essential for expanding electromobility in passenger and commercial vehicle transport. As part of the “AKS-Bipolar” research project, researchers from the University of Stuttgart and the Fraunhofer Institute for Physical Measurement Techniques in Freiburg as well as thyssenkrupp System Engineering and Chemische Werke Kluthe are looking for solutions to reduce rejects in the production of metallic bipolar plates and to provide the high component quantities required for the energy revolution. The project has a total volume of around EUR 1.43 million and is funded by the German Research Foundation (DFG) and the Fraunhofer Society as part of the trilateral transfer projects.

“Baden-Württemberg is a leader in research and science. Because here is where the raw materials of the future are supplied: knowledge, creativity, and innovation. The state government supports structural and technological change and the associated transformation of our industrial location. The research on improving the production of bipolar plates conducted at the University of Stuttgart as part of the trilateral DFG project is contributing to expanding high-performance electromobility and the key technology of fuel cells. Our excellent scientists show how research projects can be approached and implemented in order to apply new knowledge and thus advance our federal state,” says Science Minister Theresia Bauer.

A fuel cell consists of numerous stacked membrane electrode assemblies (MEA) in which chemical energy is converted into electrical energy. Between these units, bipolar BPP are arranged to supply the necessary reaction gases and drain the resulting water. In modern fuel cell systems, 300–600 BPP are installed depending on the type and size.

For a long time, BPPs made of graphite dominated the market. However, the trend is moving towards metallic BPPs because of their lower cost and higher conductivity. In order to produce these BPPs, the researchers are using metal forming processes that enable lower costs and significantly faster cycle times than machining processes. However, in sheet metal forming, even slightly fluctuating process parameters can lead to defects such as tearing, wrinkling, or springback effects. These complicate the assembly of the cell stacks.

Overall system for process control and quality assurance

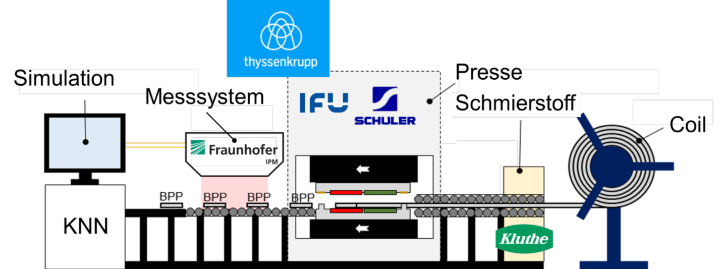

So far, most defect patterns of metallic BPP cannot be consistently detected or avoided. That’s why quality inspection is carried out downstream in cost- and time-intensive sample tests. Against this background, the researchers in the “AKS-Bipolar” project (Active process control in the series production of high-precision embossed bipolar plates) are developing an overall system for active process control and quality assurance. They plan to integrate full-surface 3D measurement technology directly into the production line of the components and map all process stages in an overall simulation (tool chain).

The project partners are using highly accurate 3D data – which is available for the first time on a large scale and in real time thanks to the digital–holographic sensor technology of the Fraunhofer IPM. These are compared quickly and accurately with simulation results used for process design at the Institute for Metal Forming Technology (IFU) at the University of Stuttgart. Here, the IFU uses the findings from numerous research projects in the fields of sheet metal and solid forming, including two previous DFG projects on the modeling of sheet metal materials.

Based on this data, the simulation tool chain to be developed in the project generates and optimizes a digital twin of the forming process under consideration. With this, recurring manufacturing problems such as cracks, wrinkles, or the springback effect are recorded numerically, and suitable countermeasures are introduced in a targeted manner.

The success of the project will be demonstrated by means of a demonstrator on a specific, industrial manufacturing example. To this end, an experimental system is being set up – first on a laboratory scale and later on an industrial scale.

With the trilateral projects launched in 2019, the German Research Foundation (DFG) and the Fraunhofer Society are promoting the transfer of findings from DFG-funded projects to industry. In this year's third round of calls for tender, 24 project outlines were received. Five of the projects were approved for funding.

Expert Contact:

Prof. Dr.-Ing. Mathias Liewald MBA, University of Stuttgart, Institute for Metal Forming Technology, Tel.: +49 711 685-83840, E-Mail