Fluctuating demand, supply bottlenecks, individualized products: being able to produce economically even in the face of dynamic changes poses challenges for the automotive industry and its suppliers. The project Software-defined Manufacturing for the Automotive and Supplier Industry (SDM4FZI) is developing solutions to ensure fast, flexible, and efficient production. The project involves a total of 30 companies, who have come together to pool their expertise, led by Bosch and with the Karlsruhe Institute of Technology (KIT) and the University of Stuttgart as scientific partners. The German Federal Ministry of Economic Affairs is funding the project with a total of 35 million euros.

The goal of the SDM4FZI project is to decouple software and hardware to flexibly plan, control and change everything from individual elements of production systems to entire factories. This should enable automobile manufacturers to switch more quickly between models and products and to produce a wider range of alternatives. The German Federal Ministry for Economic Affairs and Energy is funding the project with a total of around 35 million euros.

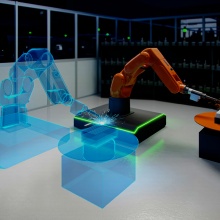

The basis for maximum adaptability is the complete separation of production system hardware and the controlling software. Software-defined manufacturing (SDM) works with digital twins, i.e. virtual images of the existing hardware, which can be used to automatically derive, test and distribute the appropriate software. This saves development time, resources, energy, and costs.

The software-defined manufacturing method used in SDM4FZI was developed by the Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW) at the University of Stuttgart, and Bosch. The project began with joint preliminary work, and has now been initiated by the ISW and the wbk Institute of Production Science at KIT, within the framework of the Mobility of the Future Innovation Campus (ICM).

Production OT with Reference Architecture Model and Software-defined Manufacturing capabilities

The University of Stuttgart, which is represented by a total of four institutes in the SDM4FZI project, managed by the Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW), focuses on the two SDM core technologies: the Reference Architecture Model and Production OT (Operational Technology). "Digital twins represent a key element of the SDM concept," explains the head of the ISW, Professor Alexander Verl. "They describe products, processes and production systems by means of data, information and behavioral models that are developed throughout the entire machine or product life cycle."

A consistent blueprint (reference architecture) ensures interoperability across the entire supply chain. Production OT capable of SDM enables automated-generated software to be distributed to production systems interoperably and in real-time. This requires entirely new infrastructure with open control architectures and continuous communication from sensor to cloud.

"The large number of project partners proves how important software is for the manufacturing of the future," emphasizes Michael Neubauer, scientific coordinator from the ISW at the University of Stuttgart. "We are working on pioneering approaches that improve the competitiveness of German companies." For example, the solutions developed at the Arena 2036 research campus will be transferred from the institutes to the automotive and supplier industries.

At the University of Stuttgart, the ISW and the Institute of Industrial Manufacturing and Management (IFF) contribute their core competencies from the fields of software and automation engineering for production engineering. The Institute of Industrial Automation and Software Engineering (IAS) and the Institute of Software Engineering (ISTE) offer a more information technology-oriented view of automation technology, thus offering a different perspective.

Versatile production through software-defined manufacturing

In particular, the scientists at KIT focus on the design of software and hardware in modern, digitized production. "In particular, we are investigating how production versatility can be increased by a targeted decoupling of software and hardware, i.e., how this can be adapted to changing framework conditions," explains Professor Gisela Lanza from the wbk Institute of Production Science at KIT. Central to this is the virtual mapping of components and systems in production using so-called digital twins, and their interaction with digital images of products and technologies along the entire value chain. The wbk team is also investigating the extent to which quality control for complex manufacturing processes can be supported by the separation of software and hardware and the integration of functional models. In addition, the researchers at KIT are also involved in the fields of robotics and handling at the Institute of Materials Handling and Logistics Systems, and at the Institute of Anthropomatics and Robotics - Intelligent Process Automation and Robotics, as well as with cloud integration and the connection to Gaia-X at the Institute of Applied Informatics and Formal Description Methods.

Expert Contact:

University of Stuttgart: Prof. Dr. Alexander Verl, Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW), Tel.: +49 (0)711 685-67301, E-Mail

Karlsruhe Institute of Technology (KIT): Prof. Dr. Gisela Lanza, wbk Institute of Production Science, Tel.: +49 (0)721 608-44011, E-Mail

Further informationen about project SDM4FZI

German information about Innovationscampus Mobilität der Zukunft (ICM)