Conventional plastic packaging is manufactured using oil, and harms the environment as plastic waste after use. The new research project “SusPackaging” at the University of Stuttgart wants to develop biocompatible packaging materials which have sustainably-produced substrates such as fats and carbohydrates as their base material and can completely biodegrade in just a few months. Bacteria play a key role in this process.

The growing mountains of plastic on our planet, and especially in the oceans, is one of the biggest environmental problems facing the world today. What makes this such a big problem is that conventional plastics in nature often last for decades or even centuries, because they do not biodegrade. So-called “biodegradable bioplastics” promise a solution to this problem. These bioplastics protect nature in two ways. Firstly, they are not based on petrochemicals, but have sustainably-produced substrates such as fats and carbohydrates as their base material. And secondly, they can completely biodegrade in nature within a few months.

This is the starting point of the "SusPackaging" project. It is formed by the Institute for Microbiology at the University of Stuttgart together with the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB and other institutes, as well as ecologically-oriented cosmetics companies such as Wala and Weleda, and is funded by the German Ministry of Education and Research (BMBF) with more than 2 million euros.

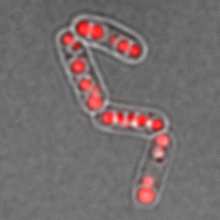

The scientists have set themselves the goal of developing biocompatible packaging materials made from sustainable base materials. The focus of the research is on bioplastics made from polyhydroxy fatty acids (polyhydroxyalkanoates, PHAs). These consist of microorganisms – specifically those made of wood waste. They also biodegrade very well in nature.

Waste is turned into substrates for bacteria

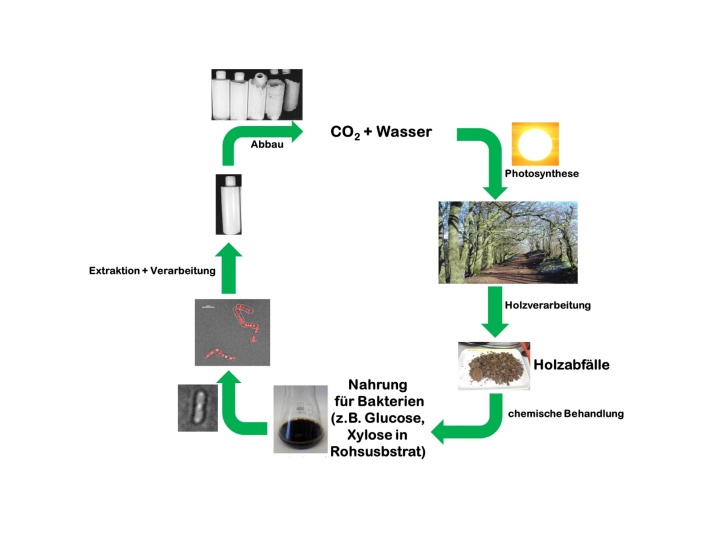

The project partners examine both the production of these biopolymers as well as their extraction from bacterial cells, for which a solvent-free process was developed at the Fraunhofer IGB specifically for the project under the leadership of Dr. Vásquez-Caicedo. The aim is a recycling economy. First of all, water and carbon dioxide are initially fixed as wood during photosynthesis. Substrates for the bacteria are then produced from waste which results from the production of wood, which are then used to produce the PHAs that are mineralized into water and carbon dioxide again at the end of the biodegrading process in nature. Experiments were carried out with a variety of bacterial strains, which grow by consuming various different food sources and which different PHA polymers can be made from. The composition of the PHAs has a major influence on the processability and usefulness of the packaging products.

Researchers have been able to develop production processes for two PHA copolymers (polymers made from more than one component) which are easy to process, and with which the bacterial strains have developed growth and productivity rates which are just as high as with substrates made entirely from carbohydrates. “In this way, we can demonstrate that these waste products are very well suited to producing high-quality bioplastics using bacteria by means of upscaling. This makes the process good for the environment as well as not using too many resources”, explain the project managers Dr. Dieter Jendrossek and Dr. Felix Becker from the Institute of Microbiology at the University of Stuttgart. Now the team wants to carry out the process on a bigger scale for the first time along with the project partners, as well as optimizing the production process. “Our target is high-quality and environmentally-friendly packaging, which for example can be used for eco-friendly cosmetics.”

Expert Contact:

apl. Prof. Dr. Dieter Jendrossek, University of Stuttgart, Institute of Microbiology, Tel. +49 (0) 711 685-65483, Email Prof. Jendrossek

Dr. Felix Becker, University of Stuttgart, Institute of Microbiology, Tel. +49 (0) 711 685-65481, Email Dr. Becker