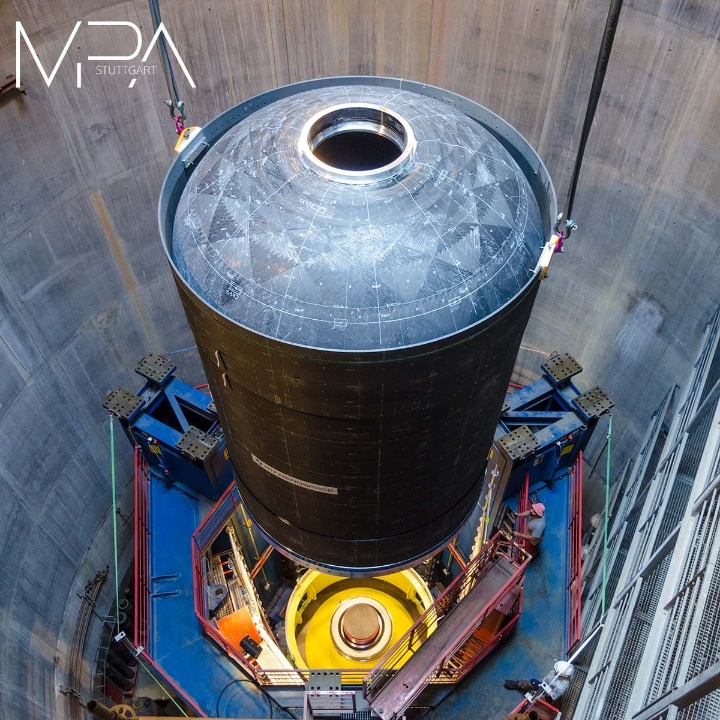

The pressure was released with a loud bang – in the booster of the new European launch vehicle Ariane, and in the testing personnel of the Materialprüfungsanstalt or MPA (Materials Testing Institute) of University of Stuttgart and MT Aerospace AG. The rupture test on 19 July 2017 at the MPA on the Vaihingen Campus was the successful conclusion of a several-day function test of the technology demonstrator for the new Ariane, which is wound from carbon fibers.

In the days prior, the booster was subjected to different pressure levels and successfully satisfied all functional and safety requirements. Now it was deliberately pushed to the point of rupture with immense overpressure, an event that was eagerly observed by all involved engineers and technicians of the MPA and of MT Aerospace AG. After all, a spectacular test like this is not something you see every day. Of course there is more to it than just the excitement of experimentation: The bang – or more precisely: the internal pressure that makes the booster rupture – answers the question of how great the safety reserves really are compared to the specifications.

The booster satisfied all requirements and exceeded all targets. For the MPA, this result is gratifying in more ways than one. MPA Director Prof. Stefan Weihe says: “This test once again confirmed our capabilities as a testing institute for complex testing with high requirements regarding testing technology and safety. I am proud of the achievements of our engineers and technicians over the past weeks during the preparation and implementation of this test.”

The employees of MT Aerospace AG are now returning to Augsburg armed with lots of testing data, which can be used for further optimization efforts. Apart from applied research, the students at University of Stuttgart also benefit from the project, because these experiences will be used in the Institute’s teaching program and enthuse young engineers for their chosen profession.

Expert Contact:

Dr. Geert Schellenberg, Materialprüfungsanstalt University of Stuttgart, Tel.: +49 711/685 62576, geert.schellenberg@mpa.uni-stuttgart.de