Short distances, joint use of infrastructure and a team of combined brains thinking outside the box – this is the recipe for success of the project house NanoBioMater of the University of Stuttgart, in which intelligent biocompatible function materials are jointly developed for medical technology, diagnostics and environmental analysis by biologists, chemists, material scientists and engineers. The Carl-Zeiss Foundation supports the project with a funding amount of 750,000 Euros.

Prof. Wolfram Ressel thanked the Carl-Zeiss Foundation for the aid commitment and said: “The project house NanoBioMater combines successful individual initiatives that have existed up to now and bilateral cooperations in the field of biomaterials with everything to do with the University of Stuttgart. The funding amount of 750,000 Euros not only offers the opportunity of enhancing the international visibility of Stuttgart material sciences activities, but the project house NanoBioMater is also able to offer the basis for a successful acquisition of a future trans-regional special research field at the DFG through expedient preparatory work.”

Under the management of Prof. Sabine Laschat (Institute of Organic Chemistry) and Prof. Thomas Hirth (Institute of Interfacing Engineering and Plasma Technology), a core team comprising two university lecturers, Prof. Christina Wege (Biological Institute) and Prof. Günter Tovar (Institute of Interfacing Engineering and Plasma Technology and Fraunhofer Institute for Interfacial Engineering and Biotechnology) as well as three post-doctoral researches working in an interdisciplinary way is to press ahead with the development of new hydrogels in the project house NanoBioMater.

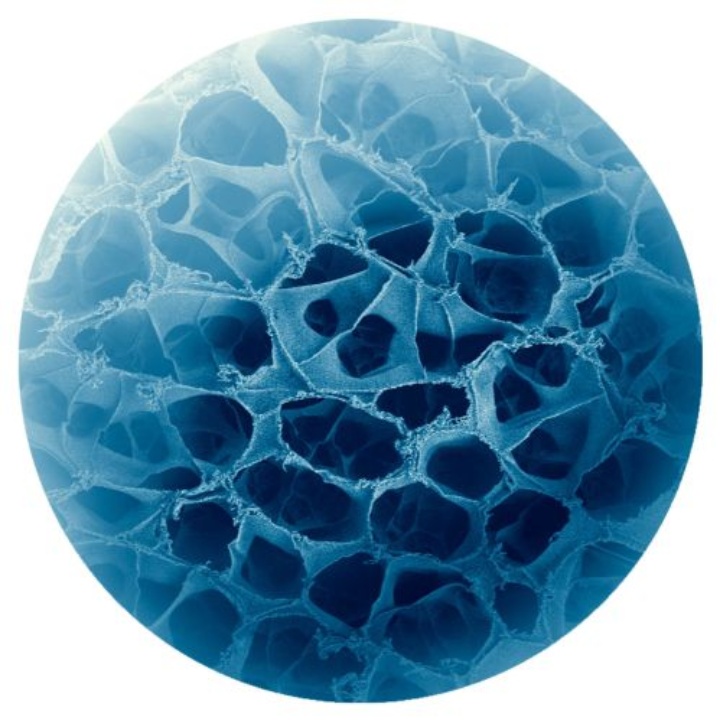

Natural biomaterials were created and optimised in the course of evolution. They are coordinated to their natural functions scale-independent from the molecular level on a nanometre scale through meso, micro up to macro sizes in compilation and structure. In order to support or even replace diseased organs, medical technology predominantly concentrates today on hard synthetic materials, such as metals, ceramics or polymers as well as hybrid materials from these components. The human body, however, is made up of tissues comprising cellular and extracellular, complex biomaterials. Water makes up 70 % of the human body mass; biological substances therefore appear mainly in the form of hydrogel-like structures that represent soft material per se. Hydrogel-based materials that could be produced in a biocompatible way and in almost any structure and form, therefore open up the way to urgently needed supplementary components up to the complete organ. Due to the demographic development, the declining availability as well as the risks of donor organs and in order to reduce the number of animal experiments, there is a constantly increasing need for such “ tailor-made artificial tissue” on a hydrogel basis. In addition, these are an ideal mix for biochemical detection and catalyst reactions, enabling diagnostics with bio-affine peptides and antibodies as well as enzymatic activities. In this way they also represent important components of miniaturised biosensors and "Lab-on-a-Chip" systems for environmental, food and medical analytics.

The focus of the Stuttgart researchers, supported by colleagues from the Institute of Material Sciences, Physical Chemistry, Polymer Chemistry, Technical Biochemistry and the Max-Planck Institute for Intelligent Systems as well as by a number of external cooperations with scientific facilities and companies, is initially to develop the molecular design of hydrogels, i.e. new synthetic polymer systems and low molecular cross-linkers, to optimise monomer components and to convert to new hydrogels that control the resulting gel structure and its tendency to swell and elasticity. Suitable material types are then used to develop hydrogel formulations with extended application potential. In this way super porous hydrogels are manufactured, which could serve as storage or reaction spaces. Through new processing methods for the porous hydrogel systems, in particular spray drying and inkjet print, spatially defined macroscopic systems are developed for various applications. Plant virus derivatives (e.g. derived from tobacco mosaic virus) hereby serve as robust and simultaneously “intelligent” framework components and can lend the hydrogel tailor-made sensory properties or convert it in a transport system for medicaments. Peptides conveying mineralisation that were “copied” from nature from the adhesive proteins of mussels and barnacles as well as mineral-eliminating cells of marine organisms (corals, sea urchins) are to be used to influence the porosity of the gels and to manufacture locally hardened gel capsules. Moreover, along with the scientific processing the project house NanoBioMater makes the necessary infrastructure of appliances and analytical instruments available, takes care of questions of biocompatibility and makes contacts to users, external cooperation partners and industrial companies. Conferences and workshops are held for young researchers, cooperating researchers and companies, international experts and interested guests.

Further information:

Prof. Sabine Laschat, University of Stuttgart, Institute of Organic Chemistry,

Tel. 0711/685-64565, Email: sabine.laschat [at] oc.uni-stuttgart.de

Prof. Thomas Hirth, University of Stuttgart, Institute of Interfacial Engineering and

Plasma Technology,

Tel. 0711/970-4400, Email: thomas.hirth [at] igb.fraunhofer.de

Dr. Hans-Herwig Geyer, University of Stuttgart, University Communication,

Tel. 0711/685-82555, Email: hans-herwig.geyer [at] hkom.uni-stuttgart.de